1. Desktop small devices, particularly spot welding robots, have started to make their way into the industry one after another. Traditional PCBA processing firms still rely heavily on numerous hand-soldering positions.

1. Handling double-sided plug-ins and components that are sensitive to high temperatures can lead to low efficiency and increased costs. Since 2021, XYZ platform or horizontal multi-joint spot welding robots have begun to emerge. With customized tooling and fixtures, these robots can effectively replace manual labor, addressing hand welding challenges in large-scale orders while rapidly enhancing the reliability and consistency of solder joints.

2. The role of a PE engineer is crucial. A skilled PE engineer can generate significant value for the company daily. For specific PCBA circuit board products, PE engineers evaluate production processes and techniques, offering targeted improvement suggestions that can substantially enhance efficiency and lower costs. Many mid-tier manufacturing firms often fall into empirical management practices, resisting advanced management models or lacking insights. Consequently, few companies employ dedicated PE engineers. As organizations increasingly focus on efficiency, the demand for PE engineer positions has steadily grown.

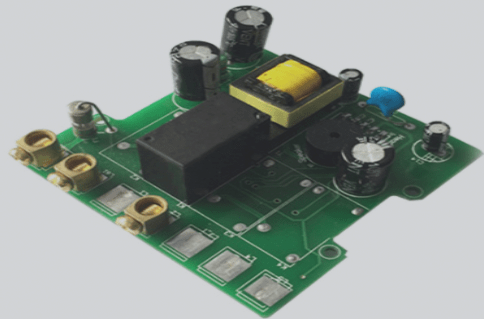

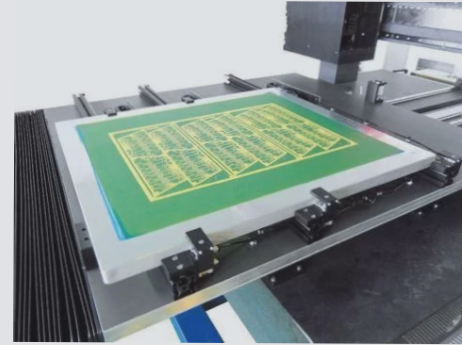

3. Quality and efficiency of equipment have become top priorities. When comprehensive process changes are not feasible in the short term, enhancing equipment utilization and stability becomes essential. Consequently, PCBA electronics manufacturing firms are opting for more mid-to-high-end equipment to offset losses stemming from process shortcomings.

4. Informational aids have emerged as powerful tools for process monitoring. Informatization plays a vital role in implementing processes effectively. By utilizing ERP, MES, and similar systems, job flow transfer becomes smoother, information communication more transparent, and product quality control history clearer. An increasing number of PCBA companies are investing in informatization software solutions to boost their core competitiveness.

Any significant transformation within a company fundamentally hinges on talent. Before leadership makes decisions, it’s essential to have capable key personnel to facilitate implementation. Otherwise, resistance during reform efforts can undermine promising initiatives. PCBA circuit boards are critical components in the manufacturing industry, aligning with the goals of the national Manufacturing 2025 strategy. Thus, evolving into an outstanding electronics manufacturing firm with core competitiveness in efficiency, cost, and quality is a pressing necessity.