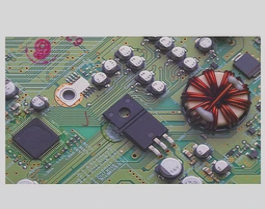

After extensive use of automated PCBA soldering machines, there are instances where a small number of local bad solder joints or high-temperature sensitive components still necessitate the traditional hand soldering process for remediation. Beyond just tin soldering, hand soldering broadly encompasses silver soldering and welding as well. Historically, the U.S. Navy placed significant emphasis on this type of manual work, establishing numerous standard operating procedures (SOPs) and stringent systems for examinations, certifications, and licensing. Their regard for practical craftsmanship was matched only by their respect for theory and academia.

1. Hand Welding with Soldering Gun

This is the most fundamental welding technique, with its primary tool, the soldering gun, also referred to as a soldering iron. The heating element and the tip of the soldering iron provide sufficient heat to the solder wire and the workpiece, facilitating high-temperature welding. As the transformer in the soldering gun generates electromagnetic waves during the heating process, it is crucial for the tool to possess effective isolation features to prevent “Electric Overstress” (EOS) to the sensitive components on the PCB surface.

1. Or “Electrostatic Discharge” (ESD) and other hazards. When selecting a soldering gun, various factors must be considered, including the shape of the soldering iron tip suited for the processing type, the temperature control sensitivity (±5 degrees Celsius), the speed of heat conduction, and the quick, adequate, and stable recovery temperature before operation (Idle Temp.). Additionally, ease of use and maintenance are important considerations.

2. Solder Wire consists of an alloy with various tin-lead weight ratios, containing a solid flux core within the metal wire-shaped solder that ensures strong mechanical solder joints. It’s essential to check whether the flux is corrosive and if the insulation resistance of the residue after soldering is sufficient to prevent poor electrical insulation in subsequent PCBA assemblies. In the future, “No Clean” flux may become necessary. Evaluation methods can be found in the “Moisture and Insulation Resistance” section 2.6.3 of IPC-TM-650. If the flux in the solder wire proves inadequate, additional liquid flux can be applied, but one must be cautious of potential ion contamination from such flux.

3. Hand welding process and key points for the torch:

(1) Clean the rust-free chromium iron tip and solder wire before contacting the soldering position to ensure molten tin adheres and fills quickly. Afterward, remove any excess solder beads from the tip using a damp sponge.

(2) Use an appropriate amount of solder wire, ensuring even dispersion without excess. The flux aids both cleaning and heat transfer.

(3) The soldering iron tip must maintain continuous contact with the soldering area to provide enough heat for even solder distribution.

(4) Be cautious when removing the welding torch to prevent disturbing the solder joints before they solidify, as this could compromise their strength.

(5) For PCBs assembled with single-sided components and larger soldering areas, the unpopulated side can be preheated on a hot plate to expedite the process and minimize overheating damage. A small hot air blower can also be used for preheating.

(6) The soldering iron tip serves as a tool for heat transfer and solder filling, so it should maximize contact area to minimize heat transfer time loss. To enhance solder material conveyance efficiency, the surface must remain clean, avoiding residue accumulation. If the tip becomes oxidized or excessively contaminated, it must be replaced.

(7) When manually welding small PCB components or thin leads, additional temporary heat dissipation accessories, such as metal alligator clips, can be used to prevent overheating damage.

1. Hand Welding with Soldering Gun

This is the most fundamental welding technique, with its primary tool, the soldering gun, also referred to as a soldering iron. The heating element and the tip of the soldering iron provide sufficient heat to the solder wire and the workpiece, facilitating high-temperature welding. As the transformer in the soldering gun generates electromagnetic waves during the heating process, it is crucial for the tool to possess effective isolation features to prevent “Electric Overstress” (EOS) to the sensitive components on the PCB surface.

1. Or “Electrostatic Discharge” (ESD) and other hazards. When selecting a soldering gun, various factors must be considered, including the shape of the soldering iron tip suited for the processing type, the temperature control sensitivity (±5 degrees Celsius), the speed of heat conduction, and the quick, adequate, and stable recovery temperature before operation (Idle Temp.). Additionally, ease of use and maintenance are important considerations.

2. Solder Wire consists of an alloy with various tin-lead weight ratios, containing a solid flux core within the metal wire-shaped solder that ensures strong mechanical solder joints. It’s essential to check whether the flux is corrosive and if the insulation resistance of the residue after soldering is sufficient to prevent poor electrical insulation in subsequent PCBA assemblies. In the future, “No Clean” flux may become necessary. Evaluation methods can be found in the “Moisture and Insulation Resistance” section 2.6.3 of IPC-TM-650. If the flux in the solder wire proves inadequate, additional liquid flux can be applied, but one must be cautious of potential ion contamination from such flux.

3. Hand welding process and key points for the torch:

(1) Clean the rust-free chromium iron tip and solder wire before contacting the soldering position to ensure molten tin adheres and fills quickly. Afterward, remove any excess solder beads from the tip using a damp sponge.

(2) Use an appropriate amount of solder wire, ensuring even dispersion without excess. The flux aids both cleaning and heat transfer.

(3) The soldering iron tip must maintain continuous contact with the soldering area to provide enough heat for even solder distribution.

(4) Be cautious when removing the welding torch to prevent disturbing the solder joints before they solidify, as this could compromise their strength.

(5) For PCBs assembled with single-sided components and larger soldering areas, the unpopulated side can be preheated on a hot plate to expedite the process and minimize overheating damage. A small hot air blower can also be used for preheating.

(6) The soldering iron tip serves as a tool for heat transfer and solder filling, so it should maximize contact area to minimize heat transfer time loss. To enhance solder material conveyance efficiency, the surface must remain clean, avoiding residue accumulation. If the tip becomes oxidized or excessively contaminated, it must be replaced.

(7) When manually welding small PCB components or thin leads, additional temporary heat dissipation accessories, such as metal alligator clips, can be used to prevent overheating damage.