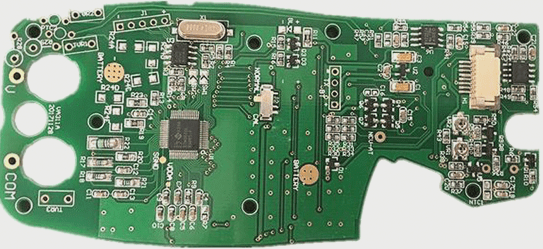

The Latest Developments in PCB Manufacturing Processes

1. Film Plate Making for PCB Production

- Base map drawing: Designers draw base maps, crucial for quality processing.

- Photoengraving: Utilizes drawn base maps to create photo plates through a series of processes like exposure, development, and fixing.

2. Graphics Transfer for PCB Production

- Screen Printing Process: Involves applying a layer of paint or glue film to transfer the circuit pattern.

3. Optical Methods for PCB Production

- Direct Photosensitive Method: Surface treatment, exposure, and development are key steps before etching.

- Photosensitive Dry Film Method: Uses a film with photosensitive adhesive for PCB production.

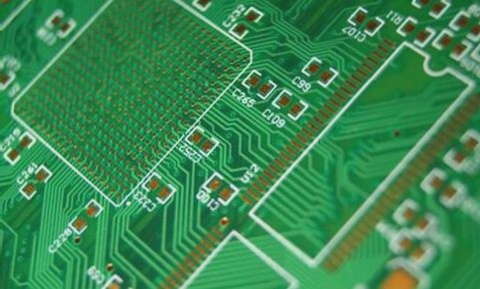

- Chemical Etching: Utilizes chemical solutions to remove unnecessary copper foil and form patterns.

4. Through-Hole and Copper Foil Treatment

- Metallized Holes: Essential for electrical connectivity in double-sided and multi-layer PCB boards.

- Metal Coating: Enhances conductivity, solderability, and wear resistance of printed circuits.

5. Soldering and Solder Mask Treatment

The PCB manufacturing process involves various steps like film plate making, graphics transfer, through-hole treatment, and soldering. These processes ensure the production of high-quality PCB boards that meet specific requirements. Recent advancements in PCB manufacturing have streamlined these processes, leading to more efficient and reliable production methods.

PCB Surface Treatment Options

Once the PCB board surface has been coated with metal, additional treatments may be necessary to ensure optimal performance.

- Flux Application: Applying flux can enhance solderability, making the soldering process more efficient.

- Solder Resist Coating: Solder resist coatings are essential for protecting the board surface and ensuring precise soldering, especially on high-density lead-tin alloy boards.

Solder resist coatings are available in two main types:

- Heat-Curing: These coatings require heat to cure properly.

- Light-Curing: Some coatings can cure with exposure to light.

Typically, solder resist coatings come in shades of dark green or light green, providing options for different aesthetic preferences.