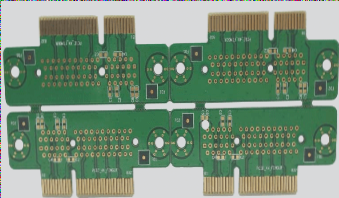

DFM (Design for Manufacturability) refers to design for manufacturing, serving as a fundamental technology in concurrent engineering. Design and manufacturing are critical components of the product life cycle. Concurrent engineering entails considering factors like product manufacturability and assemblability from the outset of the design process. Thus, DFM emerges as the key support tool in concurrent engineering. Its essence lies in analyzing design information for processability, evaluating manufacturing feasibility, and providing suggestions for design enhancement. This article will provide a brief overview of the general technical requirements for DFM in the PCB process.

1. General requirements

1. This standard establishes general requirements for PCB design and manufacturing, facilitating effective communication between CAD and CAM.

2. PCB companies prioritize design drawings and documentation as the basis for production when processing documents.

2. PCB material

1. Substrate

The PCB substrate typically consists of epoxy glass cloth copper clad laminate, known as FR4 (including single-layer boards).

2. Copper foil

a) Copper foil must be over 99.9% electrolytic copper;

b) The thickness of the copper foil on the surface of the finished double-layer board should be ≥35 μm (1 OZ); any special requirements must be specified in the drawings or documentation.

# 3. PCB Structure, Dimensions, and Tolerances

1. **Structure**

a) All design elements relevant to the PCB must be clearly indicated in the design drawings. The overall appearance should be uniformly represented using the Mechanical 1 layer (preferred) or the Keep Out layer. If both are utilized in the design file, the Keep Out layer is generally reserved for shielding without openings, while Mechanical 1 is used for forming.

b) In the design drawing, long slot holes or hollow areas should be represented by using the Mechanical 1 layer to outline the corresponding shape.

2. **Board Thickness Tolerance**

3. **Overall Dimension Tolerance**

The external dimensions of the PCB must adhere to the specifications outlined in the design drawings. If not specified, the tolerance for external dimensions is ±0.2mm (excluding V-CUT products).

4. **Flatness (Warpage) Tolerance**

The PCB’s flatness must meet the specifications provided in the design drawings.

5. **Printed Wires and Pads**

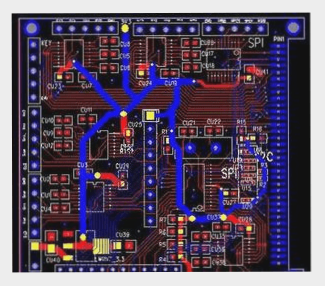

1. **Layout**

a) In principle, the layout, line width, and spacing of printed wires and pads should conform to the design drawings. However, our company will make the following adjustments: line width and pad ring width will be appropriately compensated based on process requirements. Generally, we will maximize pad size for single-layer boards to enhance the reliability of soldering.

b) If the design line spacing does not meet process requirements (excessive density may affect performance and manufacturability), we will adjust as necessary according to pre-manufacturing design specifications.

c) Our company recommends that for single and double-layer designs, the inner diameter of vias (VIA) be set to 0.3mm or larger, the outer diameter to 0.7mm or larger, with line spacing and width both set to 8mil or greater. This approach minimizes production cycles and reduces manufacturing complexity.

d) The minimum drilling tool used by our company is 0.3mm, resulting in a finished hole of approximately 0.15mm. The minimum line spacing is 6mil, and the thinnest line width is 6mil (note that this may extend the manufacturing cycle and increase costs).

2. **Wire Width Tolerance**

The internal control standard for printed wire width tolerance is ±15%.

3. **Grid Processing**

a) To prevent blistering on copper surfaces during wave soldering and PCB bending due to thermal stress, it is advisable to design large copper areas in a grid pattern.

b) The grid spacing should be greater than or equal to 10mil (not less than 8mil), and the grid line width should be at least 10mil (not less than 8mil).

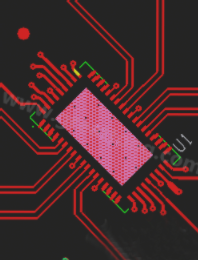

4. **Treatment of Thermal Pads**

In large-area grounding, where component legs are often connected, the treatment of these connections must account for both electrical performance and process requirements, significantly reducing the risk of excessive heat dispersion and virtual solder joints.

5. **Aperture (HOLE)**

1. **Definition of Metallization (PTH) and Non-Metallization (NPTH)**

a) Our company defaults to the following methods for non-metallized holes: When a customer specifies non-metallized properties for mounting holes in Protel99se’s advanced properties (by deselecting the plated option in the Advanced menu), we treat these as non-metallized holes. When customers utilize the Keep Out layer or Mechanical 1 layer to indicate hole punching (without a separate hole), we also treat these as non-metallized holes. If NPTH is placed near the hole, we consider the hole as non-metallized. If a customer explicitly requires a specific aperture to be non-metallized (NPTH), we will comply as requested.

b) All other component holes, mounting holes, and via holes should be metallized.

2. **Aperture Size and Tolerance**

a) PCB component holes and mounting holes in the design drawings are assumed to have the final finished aperture size. The tolerance for apertures is typically ±3mil (0.08mm).

b) Via holes (i.e., VIA holes) are generally controlled by our company with no negative tolerance required, and positive tolerance controlled within +3mil (0.08mm).

3. **Thickness**

The average thickness of the copper-plated layer in metallized holes is generally no less than 20μm, with the thinnest part not below 18μm.

4. **Hole Wall Roughness**

PTH hole wall roughness is typically controlled to ≤ 32μm.

5. **PIN Hole Issues**

a) The minimum positioning pin diameter for our CNC milling machine is 0.9mm, with three positioning pin holes arranged in a triangular formation.

b) If a customer does not specify otherwise, and the aperture in the design is less than 0.9mm, we will add PIN holes at suitable locations on the blank wireless area or large copper surface.

6. **SLOT Hole Design**

a) It is recommended to use the Mechanical 1 layer (or Keep Out layer) to define the shape of the slot hole; alternatively, it can be represented by a connecting hole of the same size, ensuring that the centers of the holes are aligned horizontally.

b) Our smallest slot cutter is 0.65mm.

c) For SLOT holes intended for shielding to prevent creepage between high and low voltages, we recommend a diameter of at least 1.2mm to facilitate processing.

6. **Solder Mask**

1. **Coating Parts and Defects**

a) All PCB surfaces, except for pads, MARK points, and test points, should be coated with a solder mask.

b) If a customer uses disks represented by FILL or TRACK, corresponding graphics must be drawn on the solder mask layer to indicate areas that should be tinned. (We strongly recommend not displaying disks in non-PAD formats prior to design.)

c) If heat dissipation is needed on large copper surfaces or tin needs to be sprayed on traces, corresponding graphics must also be included on the solder mask layer to indicate where tin is applied.

2. **Adhesion**

The adhesion of the solder mask must comply with Class 2 requirements as per US IPC-A-600F.

7. **Concluding Remarks**

The above DFM technical requirements (for single and double panels) are intended solely as a reference for customers when designing PCB files. We hope to negotiate and address these aspects to enhance communication between CAD and CAM, ultimately achieving the common goal of Design for Manufacturability (DFM), which aims to shorten product manufacturing cycles and reduce production costs.

1. General requirements

1. This standard establishes general requirements for PCB design and manufacturing, facilitating effective communication between CAD and CAM.

2. PCB companies prioritize design drawings and documentation as the basis for production when processing documents.

2. PCB material

1. Substrate

The PCB substrate typically consists of epoxy glass cloth copper clad laminate, known as FR4 (including single-layer boards).

2. Copper foil

a) Copper foil must be over 99.9% electrolytic copper;

b) The thickness of the copper foil on the surface of the finished double-layer board should be ≥35 μm (1 OZ); any special requirements must be specified in the drawings or documentation.

# 3. PCB Structure, Dimensions, and Tolerances

1. **Structure**

a) All design elements relevant to the PCB must be clearly indicated in the design drawings. The overall appearance should be uniformly represented using the Mechanical 1 layer (preferred) or the Keep Out layer. If both are utilized in the design file, the Keep Out layer is generally reserved for shielding without openings, while Mechanical 1 is used for forming.

b) In the design drawing, long slot holes or hollow areas should be represented by using the Mechanical 1 layer to outline the corresponding shape.

2. **Board Thickness Tolerance**

3. **Overall Dimension Tolerance**

The external dimensions of the PCB must adhere to the specifications outlined in the design drawings. If not specified, the tolerance for external dimensions is ±0.2mm (excluding V-CUT products).

4. **Flatness (Warpage) Tolerance**

The PCB’s flatness must meet the specifications provided in the design drawings.

5. **Printed Wires and Pads**

1. **Layout**

a) In principle, the layout, line width, and spacing of printed wires and pads should conform to the design drawings. However, our company will make the following adjustments: line width and pad ring width will be appropriately compensated based on process requirements. Generally, we will maximize pad size for single-layer boards to enhance the reliability of soldering.

b) If the design line spacing does not meet process requirements (excessive density may affect performance and manufacturability), we will adjust as necessary according to pre-manufacturing design specifications.

c) Our company recommends that for single and double-layer designs, the inner diameter of vias (VIA) be set to 0.3mm or larger, the outer diameter to 0.7mm or larger, with line spacing and width both set to 8mil or greater. This approach minimizes production cycles and reduces manufacturing complexity.

d) The minimum drilling tool used by our company is 0.3mm, resulting in a finished hole of approximately 0.15mm. The minimum line spacing is 6mil, and the thinnest line width is 6mil (note that this may extend the manufacturing cycle and increase costs).

2. **Wire Width Tolerance**

The internal control standard for printed wire width tolerance is ±15%.

3. **Grid Processing**

a) To prevent blistering on copper surfaces during wave soldering and PCB bending due to thermal stress, it is advisable to design large copper areas in a grid pattern.

b) The grid spacing should be greater than or equal to 10mil (not less than 8mil), and the grid line width should be at least 10mil (not less than 8mil).

4. **Treatment of Thermal Pads**

In large-area grounding, where component legs are often connected, the treatment of these connections must account for both electrical performance and process requirements, significantly reducing the risk of excessive heat dispersion and virtual solder joints.

5. **Aperture (HOLE)**

1. **Definition of Metallization (PTH) and Non-Metallization (NPTH)**

a) Our company defaults to the following methods for non-metallized holes: When a customer specifies non-metallized properties for mounting holes in Protel99se’s advanced properties (by deselecting the plated option in the Advanced menu), we treat these as non-metallized holes. When customers utilize the Keep Out layer or Mechanical 1 layer to indicate hole punching (without a separate hole), we also treat these as non-metallized holes. If NPTH is placed near the hole, we consider the hole as non-metallized. If a customer explicitly requires a specific aperture to be non-metallized (NPTH), we will comply as requested.

b) All other component holes, mounting holes, and via holes should be metallized.

2. **Aperture Size and Tolerance**

a) PCB component holes and mounting holes in the design drawings are assumed to have the final finished aperture size. The tolerance for apertures is typically ±3mil (0.08mm).

b) Via holes (i.e., VIA holes) are generally controlled by our company with no negative tolerance required, and positive tolerance controlled within +3mil (0.08mm).

3. **Thickness**

The average thickness of the copper-plated layer in metallized holes is generally no less than 20μm, with the thinnest part not below 18μm.

4. **Hole Wall Roughness**

PTH hole wall roughness is typically controlled to ≤ 32μm.

5. **PIN Hole Issues**

a) The minimum positioning pin diameter for our CNC milling machine is 0.9mm, with three positioning pin holes arranged in a triangular formation.

b) If a customer does not specify otherwise, and the aperture in the design is less than 0.9mm, we will add PIN holes at suitable locations on the blank wireless area or large copper surface.

6. **SLOT Hole Design**

a) It is recommended to use the Mechanical 1 layer (or Keep Out layer) to define the shape of the slot hole; alternatively, it can be represented by a connecting hole of the same size, ensuring that the centers of the holes are aligned horizontally.

b) Our smallest slot cutter is 0.65mm.

c) For SLOT holes intended for shielding to prevent creepage between high and low voltages, we recommend a diameter of at least 1.2mm to facilitate processing.

6. **Solder Mask**

1. **Coating Parts and Defects**

a) All PCB surfaces, except for pads, MARK points, and test points, should be coated with a solder mask.

b) If a customer uses disks represented by FILL or TRACK, corresponding graphics must be drawn on the solder mask layer to indicate areas that should be tinned. (We strongly recommend not displaying disks in non-PAD formats prior to design.)

c) If heat dissipation is needed on large copper surfaces or tin needs to be sprayed on traces, corresponding graphics must also be included on the solder mask layer to indicate where tin is applied.

2. **Adhesion**

The adhesion of the solder mask must comply with Class 2 requirements as per US IPC-A-600F.

7. **Concluding Remarks**

The above DFM technical requirements (for single and double panels) are intended solely as a reference for customers when designing PCB files. We hope to negotiate and address these aspects to enhance communication between CAD and CAM, ultimately achieving the common goal of Design for Manufacturability (DFM), which aims to shorten product manufacturing cycles and reduce production costs.