Capacitors are essential electronic components used in modern circuits and devices. With over 250 years of history and utility, capacitors are among the oldest electronic components ever researched, designed, developed, and applied by humans. As technology advances, capacitors come in various types, each tailored to different needs. In this article, we will introduce the most common types of capacitors available in the market.

What is a Capacitor?

A capacitor is a passive component that stores electrical energy in an electric field. It consists of two conductors separated by a dielectric material. When connected to a power source, the plates accumulate charges—one plate holds a positive charge, while the other holds a negative charge. The electrical symbol for a capacitor is shown below:

The Formula for Capacitance

Capacitance is defined as the ratio of charge (Q) to voltage (V), and is mathematically expressed as:

C = Q / V

Where:

Q is the charge in coulombs,

C is the capacitance in farads,

V is the voltage between the plates in volts.

Basic Unit of Capacitance

The basic unit of capacitance is the farad (F). However, capacitance is often expressed in smaller units such as μF (microfarads), nF (nanofarads), and pF (picofarads). Since 1 F is relatively large, μF, nF, and pF are more commonly used in practical applications.

The specific conversions between these units are as follows:

1 F = 1,000,000 μF

1 μF = 1000 nF = 1,000,000 pF

The Voltage Rating of Capacitors

Each capacitor has a voltage rating, which is one of its key specifications.

- The nominal voltage ratings for non-polarized capacitors include: 63V, 100V, 160V, 250V, 400V, 600V, 1000V, and more.

- The voltage ratings for polarized capacitors are typically lower compared to non-polarized capacitors. Common nominal voltage ratings include: 4V, 6.3V, 10V, 16V, 25V, 35V, 50V, 63V, 80V, 100V, 220V, 400V, and others.

Classification of Capacitors

Based on Structure:

- Solid-state capacitors

- Variable capacitors

- Trimmer capacitors

Based on Polarity:

- Polarized capacitors: These capacitors must be connected with the correct polarity. Common types include aluminum electrolytic capacitors and tantalum electrolytic capacitors, which have distinct positive and negative terminals. When connecting, the positive terminal must be connected to the positive terminal of the power source, and the negative terminal to the negative terminal.

- Non-polarized capacitors: These capacitors can be connected in either direction in a circuit. They are typically used in applications where the voltage direction changes frequently.

Common Types of Solid-State Capacitors

Ceramic Capacitors

Ceramic capacitors are among the most widely used types. They use ceramic materials as the dielectric, which are excellent insulators for capacitor construction. Ceramic capacitors are non-polarized, meaning there is no need to consider the positive or negative polarity during installation, making them easy to use.

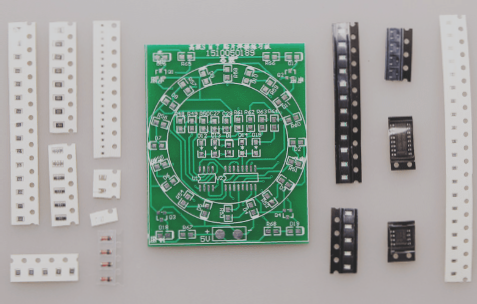

Ceramic capacitors come in two main packaging types: through-hole and surface-mount.

They are also categorized into Class I and Class II based on the dielectric material used. Common Class I ceramics include NP0, SL0, and COG, while Class II ceramics include X7R, X5R, Y5U, and Y5V.

Class I ceramic capacitors offer excellent stability with minimal changes in capacitance due to temperature, voltage, and time variations. They are ideal for high-precision applications such as resonant circuits.

Class II ceramic capacitors, on the other hand, exhibit more significant capacitance changes due to temperature, voltage, and time. These are typically used in applications where stability is less critical, such as in filtering applications.

Electrolytic Capacitors

Electrolytic capacitors feature a metal anode coated with an oxide layer that serves as the dielectric. These capacitors are polarized and classified based on their dielectric material.

Aluminum Electrolytic Capacitors – Use aluminum oxide as the dielectric.

Tantalum Electrolytic Capacitors – Use tantalum pentoxide as the dielectric.

Niobium Electrolytic Capacitors – Use niobium pentoxide as the dielectric.

Applications of electrolytic capacitors:

- Used in applications requiring large capacitance values.

- Often employed as filtering devices to reduce ripple voltage.

- Used in audio amplifiers to minimize electrical noise from the power source.

- Used to smooth input and output signals in DC circuits with weak AC components.

Film Capacitors

Film capacitors consist of one or more layers of insulating film with metal electrodes. They can be categorized based on the materials used and their structural characteristics.

Common types of film capacitors include:

- Metal Film Capacitors: These capacitors use metal films as the dielectric, with metals such as aluminum, zinc, and tin. They offer high precision, stability, and reliability, making them ideal for various electronic devices.

- Polyester Film Capacitors: These capacitors use polyester film (such as polyethylene terephthalate, or PET) as the dielectric. While cost-effective, they offer lower precision than other types.

- Polypropylene Film Capacitors: These use polypropylene film as the dielectric, offering low loss and excellent stability. They are commonly used in high-precision and high-frequency applications, such as audio equipment and electronic filters.

- Ceramic Film Capacitors: These capacitors use ceramic film, featuring a high dielectric constant and low leakage current. They perform well in high-temperature and high-frequency environments, making them suitable for power filtering and energy storage circuits.

- Polyimide Film Capacitors: Made with polyimide film, these capacitors are resistant to high temperatures and have low leakage currents. They are used in high-temperature applications such as aerospace and automotive electronics.

Each type of film capacitor has unique characteristics, and the choice of the appropriate capacitor depends on the specific circuit requirements.

Mica Capacitors

Mica capacitors use natural mica as the dielectric material, with a metal film (typically silver) applied to the mica surface as