The Importance of PCB Layering in Electronic Design

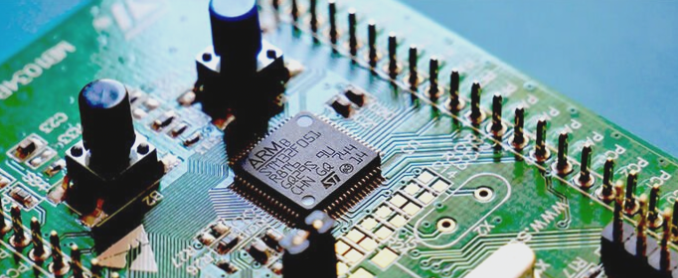

- PCB boards in modern electronic devices often consist of multiple layers for wiring, including interlayer copper foils for specialized processing.

- Understanding concepts like “multi-layer pad” and “wiring layer setting” is crucial for successful PCB design.

- Properly defining pad characteristics and turning off unused layers can simplify the design process and prevent complications.

Utilizing Vias for Layer Connection

- Via holes are essential for connecting lines between different layers of a PCB.

- Considerations like minimizing via usage and selecting appropriate via sizes based on current carrying capacity are important in circuit design.

Enhancing PCB Functionality with Silkscreen Layers

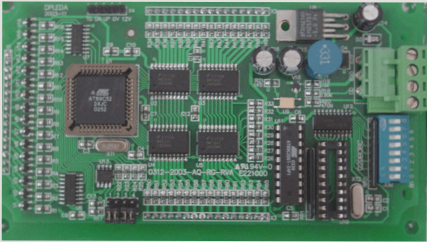

- Silkscreen layers, or overlays, provide vital information such as component labels, manufacturer logos, and production dates on the PCB surface.

- Proper silkscreen layout is key to ensuring clear markings and preventing issues during assembly and maintenance.

Optimizing SMD Packages and Pad Design

- Special considerations are needed for SMD packages with single-sided element pin holes in PCB design software.

- Customizing pad shapes and sizes based on component requirements is essential for effective PCB layout.

Differentiating Between Grid-like Filling Areas and Pads

- Network filling areas and filling areas serve distinct purposes in circuit design, with network filling areas suppressing interference and filling areas suitable for smaller areas.

- Choosing the right type of pad and filling area can optimize the performance of the PCB.

Understanding the Role of Solder Flux and Solder Mask Films

- Solder flux film improves solderability on pads, while solder mask prevents unwanted tin adhesion during soldering.

- Adjusting settings like “solder Mask Enlargement” ensures proper soldering conditions and component functionality.

Enhancing Routing Efficiency with Flying Lines

- Flying lines aid in observing automatic routing processes and optimizing component positions for efficient routing.

- They can also assist in identifying networks that require manual adjustments during production for optimal performance.