The Evolution of PCB Lamination in Modern Electronics

The field of electronic science and technology is advancing rapidly, leading to a heightened demand for more precise PCBs. Traditional single or double-layer PCB boards are no longer sufficient for today’s technological needs. Lamination, a critical process in PCB manufacturing, plays a key role in meeting these evolving demands.

Types of PCB Laminating Processes

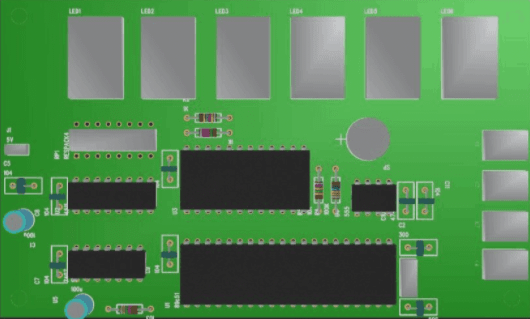

- Multilayer PCB Board: This type of PCB consists of multiple layers that are bonded together through lamination. The process involves high temperatures and pressures to create a reliable connection between the layers.

- Double-Sided PCB Board: Similar to multilayer PCBs, double-sided PCBs undergo a lamination process using photosensitive dry resist layers.

- Sequential Lamination: Used for PCBs with multiple subsets, sequential lamination involves creating each subset separately and then bonding them together with dielectric material.

- Teflon PCB (PTFE) Microwave Laminate: PTFE laminate is favored for its consistent dielectric properties, low electrical loss, and precise thickness tolerance, making it ideal for RF applications.

Key Considerations in PCB Prototyping

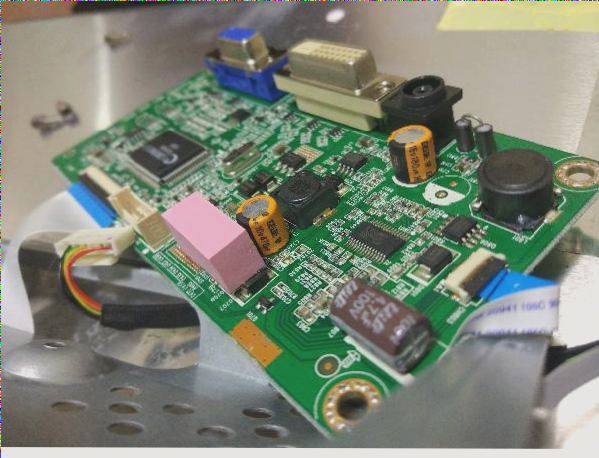

When it comes to PCB prototyping, attention to detail is crucial to ensure successful production:

- Sample Quantity: Careful assessment of the number of prototype samples needed can help manage costs effectively.

- Component Assembly Verification: Proper soldering of internal chips and components is essential for verifying functions and ensuring prototype quality.

- Electrical Testing: Thorough electrical inspections post-prototyping are necessary to validate PCB functions and minimize defects, requiring close collaboration with prototyping partners.

Overall, the evolution of PCB lamination techniques and the meticulous attention to detail in prototyping are vital for meeting the high standards of modern electronic technology.