Understanding Temperature and Humidity in Circuit Boards

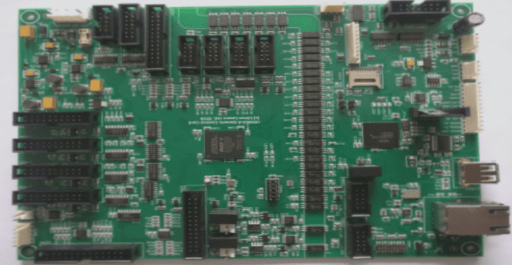

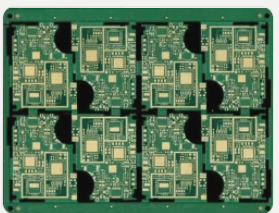

Temperature and humidity play crucial roles in the performance and longevity of printed circuit boards (PCBs). Failure to manage these factors properly can result in damage to the circuit board, leading to costly repairs and wasted time during manufacturing processes. Let’s explore insights from circuit board repair experts to better comprehend these essential aspects.

The Significance of Temperature in PCBs

Temperature measurement in PCBs has evolved significantly over the years, with platinum resistance thermometers emerging as a preferred choice for high-precision temperature sensing. Platinum’s exceptional oxidation resistance at elevated temperatures makes it ideal for accurate temperature measurements and high-temperature thermocouples in circuit board applications.

Exploring Humidity in PCBs

The humidity of a PCB consists of absolute humidity and relative humidity. Understanding the differences between these two concepts is crucial for maintaining the quality and performance of circuit boards.

Relative Humidity of PCBs

Relative humidity measures the actual mass of water vapor present in the air relative to its saturation level. It is essential to consider relative humidity when assessing the environmental conditions that PCBs are exposed to, as it impacts their functionality and longevity.

Calculating Humidity of PCBs

Humidity, focusing on the quality of water vapor per cubic meter of humid air, can be calculated using specific formulas based on water vapor density and partial pressure of water vapor at a given air temperature. Maintaining optimal humidity levels is vital for preventing moisture-related issues in circuit boards.

Common Causes of Circuit Board Failures

Various factors can contribute to circuit board failures, impacting their reliability and performance. Understanding these causes is essential for preventing issues that may arise during the operation of PCBs.

- Software: Improper software configurations with narrow margins can lead to critical parameter values, triggering fault alarms under specific operating conditions.

- Moisture and Dust: Accumulation of moisture and dust on circuit boards can affect resistance, leading to variations during thermal cycles and potential malfunctions.

- Poor Connections: Inadequate wire plugs, terminal connections, internal cable breaks, and faulty soldering can result in poor circuit board connections, impacting overall performance.

- Signal Interference: Changes in component parameters or circuit performance can reduce the system’s resistance to interference, causing errors and system failures in digital circuits.

Common Causes of PCB Failure

When it comes to PCB failure, there are four main categories to consider. By addressing these factors proactively, you can reduce the likelihood of experiencing issues with your circuit board. However, it’s important to note that certain failures may still occur due to misuse, overloading, or natural wear and tear.

If you require any assistance with PCB manufacturing, feel free to reach out to us.