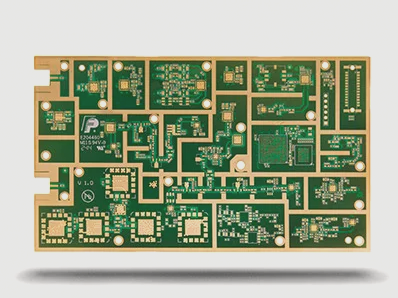

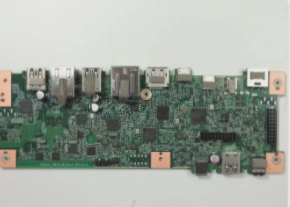

FPCA (Flexible Printed Circuit Assembly) products, specifically FPC components, represent an extension of the FPC business industrial chain, with SMT (Surface Mount Technology) being the predominant technology in the industry. SMT is a technique for mounting electronic circuits on the surface of a printed circuit board or other substrates, using surface mount components that have either no leads or very short leads (SMC/SMD for short, known as chip components in Chinese). These components are attached through processes such as reflow soldering or dip soldering. The application of SMT technology offers several advantages:

1. **High Assembly Density**: SMT allows for smaller and lighter electronic products. The volume and weight of surface-mount components are roughly 1/10 of those of traditional through-hole components. Typically, using SMT can reduce the volume of electronic products by 40% to 60% and their weight by 60% to 80%.

2. **High Reliability**: SMT components exhibit high reliability, excellent earthquake resistance, a low rate of solder joint defects, and good high-frequency performance.

3. **Reduced Electromagnetic Interference**: SMT helps in minimizing electromagnetic and radio frequency interference.

4. **Automation and Efficiency**: SMT facilitates automation, which enhances production efficiency.

5. **Resource Savings**: SMT leads to savings in materials, energy, equipment, labor, and time.

**Application of Flexible Circuit Boards**

The growing demand for lightweight, thin, compact, and small electronic products has driven FPCs to shift rapidly from military applications to civilian and consumer electronics. Recently, nearly all cutting-edge electronic products incorporate a significant number of flexible circuit boards. According to Japanese scholar Kenshi Sakura in “High-Density Flexible Printed Circuit Boards,” almost all electrical products now use flexible circuit boards, and finding even moderately complex electronic products without them is rare.

**Market Prospects of Flexible Circuit Boards**

The “Guide to Priority Development of High-Tech Industrialization Key Fields (2011)” highlights that high-density multilayer printed circuit boards and flexible circuit boards are key areas for information technology high-tech industrialization, as identified by the National Development and Reform Commission, the Ministry of Science and Technology, the Ministry of Industry and Information Technology, the Ministry of Commerce, and other related agencies. With ongoing advancements in informatization and smart construction, the demand for flexible circuit boards is expected to rise.

1. **Mobile Phone Market**: In mobile phones, FPCs are used for signal connections in components like folding and rotating parts. Currently, more than three FPCs are employed in each mobile phone. The trend toward lighter, thinner, and smaller high-function mobile phones has driven the demand for FPCs. They are used in various functions, including bends, LCD modules, camera modules, buttons, side buttons, antennas, and battery control. The hinge part of mobile phones sees the most extensive use of FPCs, often in double-sided or multi-layer designs. While the use of FPCs in buttons, camera modules, antennas, or batteries is selective, future standardization in mobile phone design will likely increase FPC usage.

2. **Automotive Electronics Market**: The rise of automotive electronics has made FPCs valuable for high-signal transmission and reliability in automotive control systems, such as dashboards, air quality monitors, audio systems, displays, and sensors. The precision and three-dimensional flexibility of FPCs are well-suited to the compact and curved wiring areas of modern vehicles.

3. **Medical Monitoring Equipment**: Medical monitoring equipment is increasingly common in large and medium-sized hospitals. With China’s economic development, there is growing emphasis on primary medical and health systems at local levels. This growth, driven by factors such as aging, the second-child policy, consumption upgrades, medical reform investment, and policy support, highlights the potential for development in the medical monitoring sector. The domestic medical device industry has substantial room for growth, making its future prospects promising.

In summary, as societal demands for informatization and intelligence continue to expand across various sectors, FPCs and FPC components are becoming ubiquitous in even moderately complex electronic products. The anticipated increase in national investment in electronic information infrastructure will further accelerate the development of the FPC and FPC component industries. Additionally, the nationwide rollout of 4G services presents new development opportunities for the flexible printed circuit board industry.