Effective Heat Dissipation Techniques for PCB Circuit Boards

Every PCB electronic device generates heat during operation, which can lead to overheating and decreased reliability if not managed properly. Effective heat dissipation is crucial for PCB design to prevent potential failures.

Heat Dissipation through PCB Material

- The commonly used PCB materials like copper-clad epoxy glass cloth substrates and phenolic resin glass cloth substrates do not efficiently dissipate heat.

- Relying on the PCB’s resin to conduct heat is not effective, especially with high-heat components mounted on the board.

Enhanced Heat Dissipation Techniques

- Adding Heat-Dissipating Copper Foil can significantly improve thermal performance, especially in power supply areas.

- Thermal Vias help transfer heat away from hot spots on the PCB.

- Exposing Copper on the Back of the ICs lowers thermal resistance, improving heat dissipation.

PCB Layout Considerations

- Place Heat-Sensitive Components in Low-Temperature Zones to minimize the impact of temperature rise.

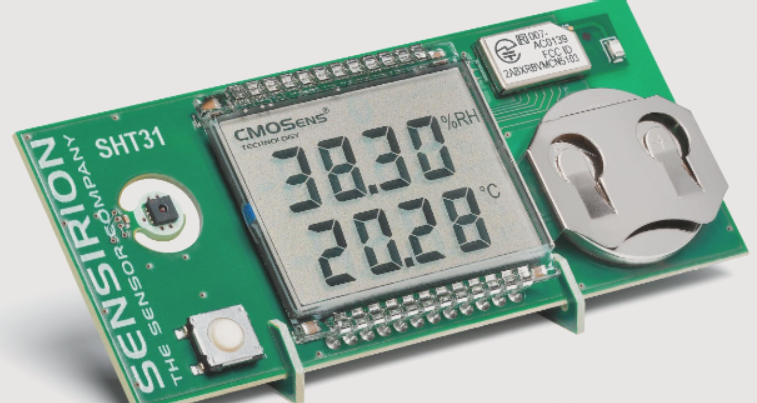

- Position Temperature Sensors in High-Heat Areas to monitor thermal performance effectively.

Optimizing Component Placement for Heat Dissipation

- Arrange devices based on their heat generation and dissipation capabilities to ensure efficient airflow.

- Position high-power devices close to the PCB edge horizontally and near the top vertically to minimize heat transfer paths.

- Consider airflow pathways and component placement carefully to optimize heat dissipation within the system.

By implementing these techniques and considerations, PCB designers can effectively manage heat dissipation and improve the reliability of electronic devices.

Optimizing Heat Dissipation in PCB Design

When designing a PCB, it is crucial to consider the placement of high-power and high-heat-generating components to ensure efficient heat dissipation. Here are some key recommendations:

Placement of Components

- Position high-power components strategically for optimal heat dissipation.

- Avoid placing them at the corners or edges unless a heat sink is nearby.

- Choose larger components for power resistors when possible.

Component Spacing

- Combine high-heat-generating components with radiators or heat-conducting plates.

- Consider adding heat sinks or heat pipes to components generating substantial heat.

- For multiple heat-generating components, use a large heat dissipation cover.

Enhancing Heat Dissipation

- Ensure the heat dissipation cover makes direct contact with components.

- Optimize heat dissipation by arranging components vertically or horizontally.

- Maximize copper foil area and increase the number of vias for efficient heat conduction.

For power resistor design, always prioritize larger components and allow ample space for heat dissipation. Distribute power dissipation evenly across the PCB to prevent hot spots and maintain consistent temperature.

While achieving perfect heat distribution uniformity is challenging, avoiding areas of excessive power density is crucial to prevent overheating. Consider performing thermal efficiency analysis using advanced PCB design software to optimize thermal management.

If you require PCB manufacturing services, feel free to contact me.