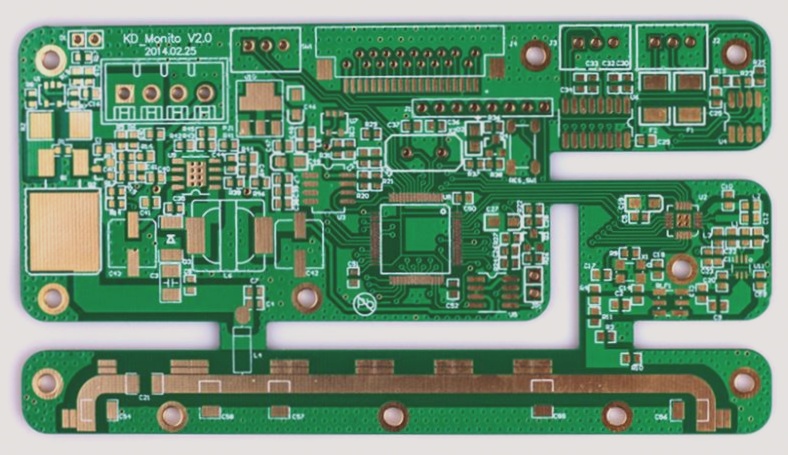

PCB Components Selection for Industrial Control Motherboards

When choosing materials for PCB components, industrial control motherboards prioritize extensively verified components that meet high standards. This ensures reliable performance under challenging conditions like high temperatures and moisture resistance. For example, industrial control motherboards utilize high-quality chip solid capacitors, tantalum capacitors, and ceramic capacitors known for their stability, long lifespan, and superior high-temperature performance. Additionally, a low-power CPU is selected to meet the demanding environmental requirements of the industrial control industry.

PCB Design for Enhanced Stability

The industrial control motherboard employs a PCB circuit board design with over 6 layers to boost resistance to electromagnetic interference and enhance electromagnetic compatibility. This design strategy ultimately enhances the overall stability of the motherboard.

Platform Selection and Interface Design

Industrial control motherboards typically opt for low-power chipsets to conserve energy and adapt to various environments. These motherboards feature customized or stacked standard interfaces like serial ports, USB, LAN, and LPT to interface with external equipment based on site requirements. They also incorporate anti-surge protection and static discharge features for different environments. Expansion interfaces such as PCI, PCIe, and Mini-PCIe support multiple expansions when paired with industrial motherboards and backplanes. Various display interfaces like VGA, LVDS, HDMI, and DVI are also included.

Storage Interface and Protection Function

Industrial control motherboards offer diverse storage interfaces such as IDE, SATA, SCSI, CF cards, and DOC to meet a range of storage needs. These motherboards feature specialized PCB designs that enable automatic restart in case of system downtime, ensuring high system stability.

Customized Solutions and Manageable Features

Custom PCB industrial control boards can address specific customer requirements, providing tailored solutions that align with unique environmental demands. Manageable industrial control motherboards offer remote, unattended automatic switching functions along with real-time management, recording, and transmission of system operating information through embedded IPMB and SMNP-1000 modules.

Enhanced Protection Features

Industrial control motherboards are designed to withstand extreme conditions like crashes, with features like watchdog automatic restart and anti-surge capabilities ensuring system stability in harsh environments. Mastering these features is essential for optimal performance.