Effective Tools for PCB Manufacturing Operations

When dealing with high-volume PCB manufacturing operations, utilizing a programming fixture can greatly enhance efficiency. This method involves the use of spring contacts, or pogo pins, to establish electrical connections between PCBs. By pressing these pins into the designated contacts on the PCB, the entire panel can be programmed simultaneously, streamlining the production and testing processes. While fixtures may incur higher costs in terms of development and construction, they are ideal for medium to high production runs.

Alternative Approach: Generic Headers

For smaller batch PCB production, an alternative to programming fixtures is the use of generic headers. This method serves as a middle ground between traditional programming heads and fixtures. Cables equipped with built-in pogo pins are employed, with one end linked to the programming source and the other end connected to the PCB contacts. This approach eliminates the necessity for tool-specific heads or custom fixtures, offering a cost-effective solution.

Challenges in PCB Manufacturing

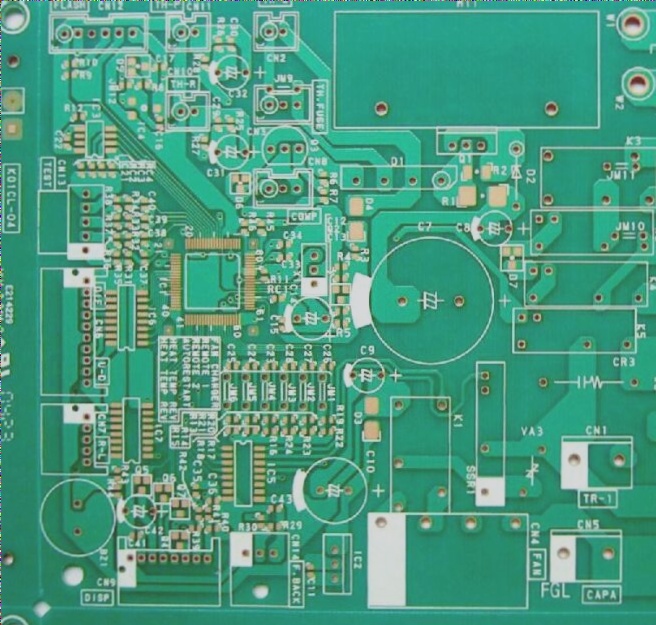

The intricate nature of PCB manufacturing poses various challenges, especially with the evolution of technology leading to the creation of smaller and more intricate devices. This trend necessitates a more refined and meticulous manufacturing approach to meet the demands of the industry.

Enhancing Customer Service and Communication

Effective customer service in PCB manufacturing involves understanding the testing process thoroughly. By actively engaging with PCB manufacturers, gaining insights into the production procedures, comprehending customer requirements, and fostering strong working relationships, one can stay updated on progress and promptly address any arising issues.

WellCircuits Limited: Your PCB Manufacturing Partner

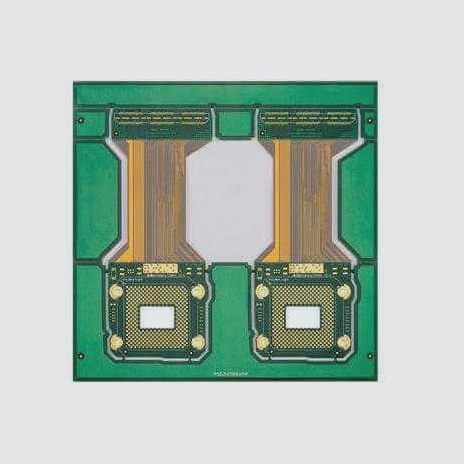

Specializing in high-precision circuit boards, WellCircuits Limited offers a wide range of products to meet diverse customer needs. From double-sided and multi-sided boards to impedance control, blind buried vias, and thick copper boards, their expertise also extends to HDI, backplanes, rigid-flex combinations, and more. With a focus on quality and innovation, WellCircuits Limited is committed to delivering top-notch PCB solutions.