The Significance of Thermal Management in PCB Design

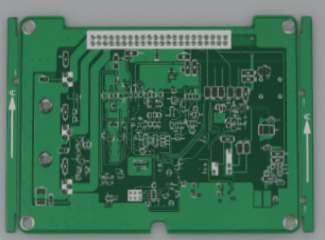

Efficient heat dissipation in PCB circuit boards is crucial for maintaining optimal performance and reliability. Failure to dissipate heat effectively can lead to overheating, reducing equipment lifespan and performance.

Factors Influencing PCB Temperature Rise

- Power Consumption: Evaluate power consumption per unit area and distribution across the board.

- Printed Board Structure: Consider dimensions and materials used.

- Board Installation: Factors like mounting methods and distance from the housing impact temperature rise.

Understanding Thermal Radiation, Heat Transfer, and Thermal Convection

Key aspects like emissivity, temperature differences, and heat transfer mechanisms play a vital role in managing PCB temperatures effectively.

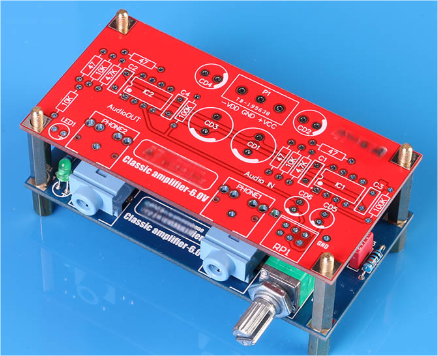

Effective PCB Thermal Design Methods

- Utilize PCB heat dissipation properties.

- Employ radiator heat conduction plates for high-heat applications.

- Consider heat sinks and fans for devices with high heating capacity.

- Optimize wiring design to enhance heat dissipation.

Key Takeaways for PCB Thermal Management

- Maintain printed board wire temperatures below 125°C.

- Explore thermal resistance plates for specialized applications.

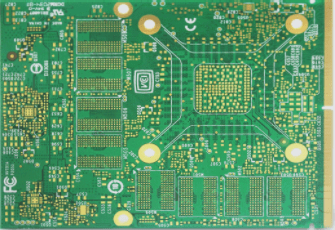

- Utilize multi-layer board structures for improved thermal performance.

- Ensure unobstructed heat dissipation channels for efficient cooling.

The Importance of Heat Dissipation in PCB Design

- Enhancing heat dissipation is crucial for reducing thermal resistance and increasing power density on circuit boards.

- Utilizing heat dissipation holes, such as via holes on pads, can improve thermal conductivity by allowing solder to reach metal heat dissipation layers efficiently.

- Consider incorporating special heat dissipation materials, especially in module power supply printed boards, to optimize heat dissipation.

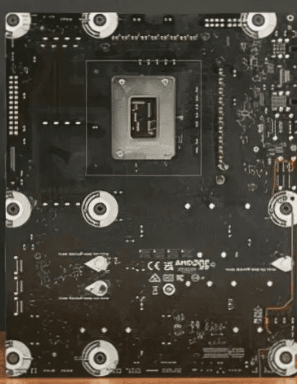

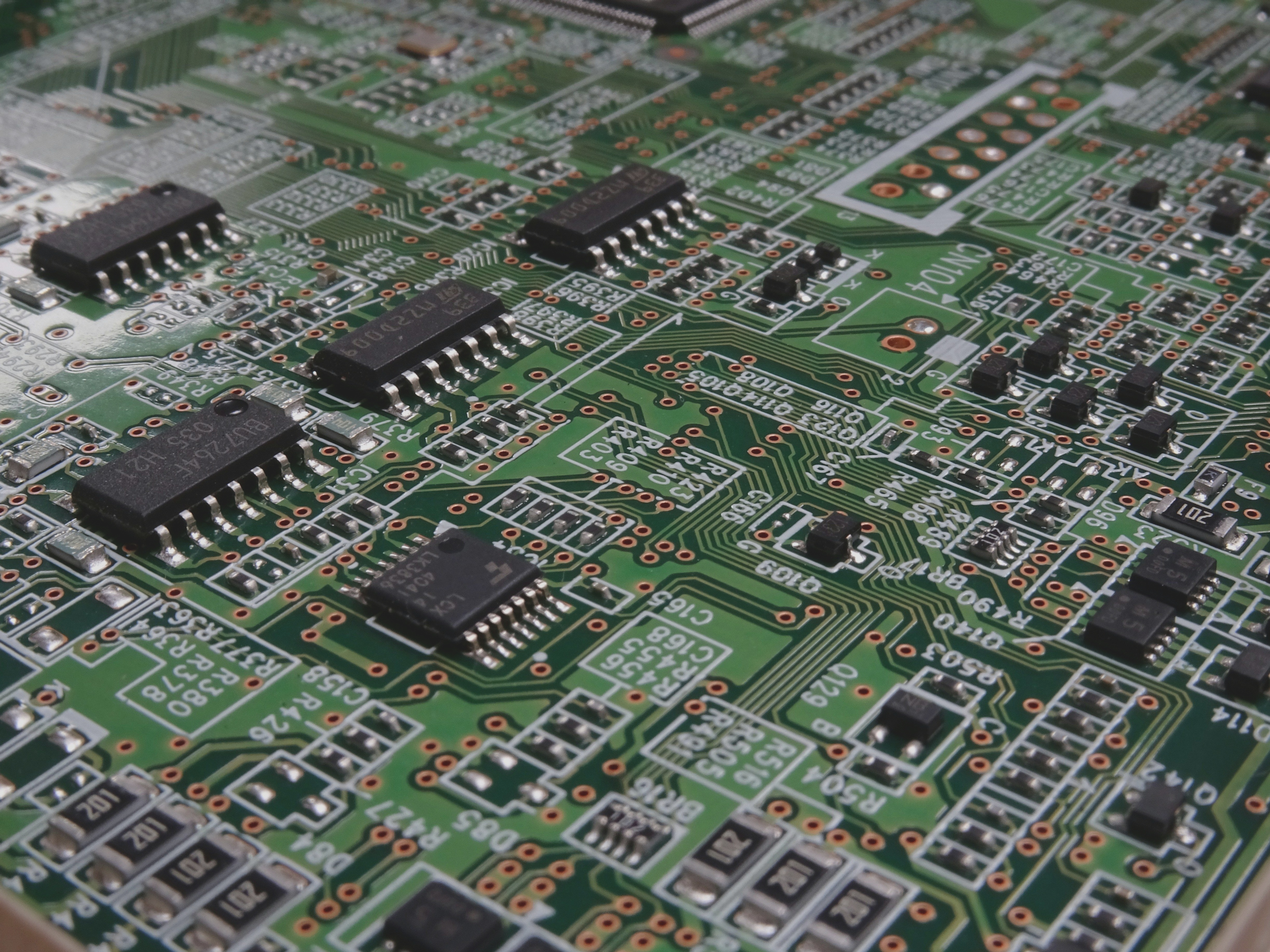

Component Layout Guidelines

- Utilize software thermal analysis for PCB design to manage internal temperature rises effectively.

- Place high-radiation components strategically on the printed board.

- Ensure even distribution of heat capacity on the board to prevent overheating in specific areas.

- Minimize heat transfer path length and maximize heat transfer cross-section for efficient heat dissipation.

- Position heat-sensitive parts away from heat sources and ensure proper ventilation for cooling.

- Consider using metal chassis for improved heat dissipation in PCB layouts.

Effective Wiring Practices

- Opt for steel plates in printed board structures for enhanced durability.

- Adhere to PCB wiring rules to maintain optimal performance.

- Plan channel width based on current density and prioritize wiring at seams for efficient heat dissipation.

- Surface-mount large current lines whenever possible or use bus bars for effective current flow.

- Reduce thermal resistance by increasing heat conduction area and applying thermally conductive materials when necessary.

- Ensure stress balance and increase thermal stress point thickness in wiring layouts.

- Implement heat dissipation stress window methods and utilize large-area copper foil for improved heat dissipation.

- Maximize heat dissipation by using larger pads for ground mounting holes and strategic placement of copper foil on printed boards.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย