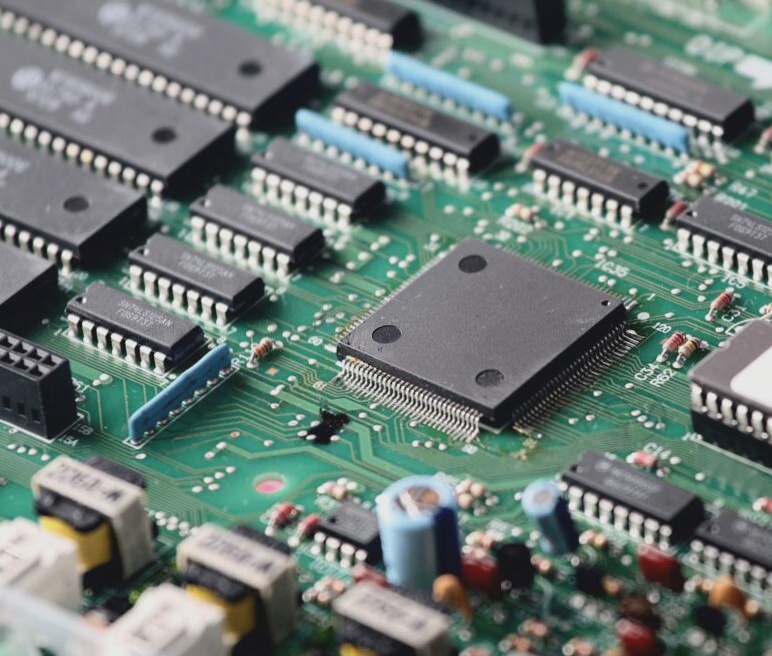

Before SMT patch processing, we often encounter situations where materials supplied by customers or purchased by the company are not vacuum-packed. Due to uncertain production timelines, these materials can easily absorb moisture during storage. If we do not perform a drying process on the PCB or components, the reflow soldering or wave soldering furnace may suddenly heat to above 200 degrees Celsius. This rapid temperature rise causes water vapor within the materials to expand quickly. As the temperature of the soldering equipment continues to increase, water vapor trapped in the PCB or components cannot escape, leading to potential issues such as PCB blistering, swelling, and even board explosion. Therefore, the main purpose of baking PCBs and components is to remove absorbed moisture to prevent deformation during the furnace process, oxidation of pads/pins, and blistering and delamination of the board. So, how should we determine a reasonable baking temperature? Below is an explanation to help you set appropriate temperature parameters for baking different components.

1. Baking time and temperature settings

1. Tape-packed components: Strip-packed ICs, transistors, and terminals without vacuum packaging and with a production date exceeding one year must be baked at 60°C for 12 hours.

2. Tray SOP, QFP, PLCC, and other ICs: Regardless of vacuum packing, baking is determined by the humidity indicator card in the tray’s vacuum package. If four or six colors show the 20% section of the card, or if three of the 10% section colors turn lavender, indicating moisture, the IC must be baked. Bake at 125°C for 8 hours. Ensure each stack of ICs is separated by at least 5 mm to allow convection and hot air circulation between layers.

3. Tray BGA: After removing the BGA, it should be baked whether it is bulk material or pallet-packaged. Place the BGA in a baking box using a tray marked with a temperature resistance of 125°C or higher. Bake at 125°C for 24 hours. If storage time is exceeded or the vacuum package is compromised, bake at 125°C for 24 hours. Ensure each stack of BGA is separated by at least 5 mm for proper convection and hot air circulation. Baked BGAs must be mounted within 4 hours.

4. PCB circuit board: 1. For substrates with a production date within 6 months but without vacuum packaging, bake at 110°C for 2 hours. 2. For substrates older than 6 months, bake at 125°C for 4 hours. 3. For main substrates and those containing BGAs, bake at 125°C for 8 hours. 4. All DIP process substrates require baking at 85°C for 8 hours. The PCBs should be placed horizontally with a maximum stack of 30 pieces. After baking, remove from the oven and cool the PCBs flat.

2. Matters needing attention:

1. Do not place flammable, volatile, or explosive materials in non-explosion-proof baking boxes, including packaging plastic bags with PCBs. Ensure equipment is not in a flammable or explosive environment to prevent accidents.

2. Avoid overloading and maintain a gap between items to ensure proper air circulation.

3. Activate the blast before heating when opening the drying box; keep the exhaust valve on top half-open during use.

4. Adhere to customer-specific baking specifications if provided.

5. PCB operators must follow baking parameters and complete the “Baking Record Form.” IPQC should monitor and confirm the baking temperature; notify engineering if deviations exceed ±5°C.

1. Baking time and temperature settings

1. Tape-packed components: Strip-packed ICs, transistors, and terminals without vacuum packaging and with a production date exceeding one year must be baked at 60°C for 12 hours.

2. Tray SOP, QFP, PLCC, and other ICs: Regardless of vacuum packing, baking is determined by the humidity indicator card in the tray’s vacuum package. If four or six colors show the 20% section of the card, or if three of the 10% section colors turn lavender, indicating moisture, the IC must be baked. Bake at 125°C for 8 hours. Ensure each stack of ICs is separated by at least 5 mm to allow convection and hot air circulation between layers.

3. Tray BGA: After removing the BGA, it should be baked whether it is bulk material or pallet-packaged. Place the BGA in a baking box using a tray marked with a temperature resistance of 125°C or higher. Bake at 125°C for 24 hours. If storage time is exceeded or the vacuum package is compromised, bake at 125°C for 24 hours. Ensure each stack of BGA is separated by at least 5 mm for proper convection and hot air circulation. Baked BGAs must be mounted within 4 hours.

4. PCB circuit board: 1. For substrates with a production date within 6 months but without vacuum packaging, bake at 110°C for 2 hours. 2. For substrates older than 6 months, bake at 125°C for 4 hours. 3. For main substrates and those containing BGAs, bake at 125°C for 8 hours. 4. All DIP process substrates require baking at 85°C for 8 hours. The PCBs should be placed horizontally with a maximum stack of 30 pieces. After baking, remove from the oven and cool the PCBs flat.

2. Matters needing attention:

1. Do not place flammable, volatile, or explosive materials in non-explosion-proof baking boxes, including packaging plastic bags with PCBs. Ensure equipment is not in a flammable or explosive environment to prevent accidents.

2. Avoid overloading and maintain a gap between items to ensure proper air circulation.

3. Activate the blast before heating when opening the drying box; keep the exhaust valve on top half-open during use.

4. Adhere to customer-specific baking specifications if provided.

5. PCB operators must follow baking parameters and complete the “Baking Record Form.” IPQC should monitor and confirm the baking temperature; notify engineering if deviations exceed ±5°C.