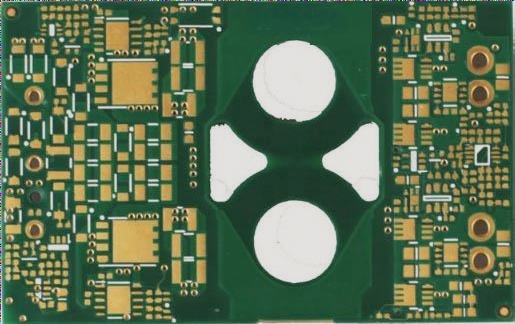

Quick Guide to PCB Circuit Board Production

Keeping up with trends in environmental protection and technology advancements, PCB manufacturers are utilizing big data to monitor and address environmental issues promptly. Embracing green production practices is essential for a sustainable future in the PCB industry.

Key Steps in PCB Circuit Board Production:

- Designing the PCB circuit diagram

- Printing onto the PCB board

- Etching the board

- Drilling holes

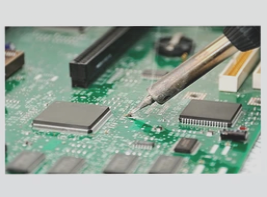

- Soldering components

- Conducting tests

Methods for Fast PCB Circuit Board Production:

There are two primary methods for rapid board production:

1. Physical Method:

Using knives and power tools to manually remove unnecessary copper. This method is labor-intensive and lacks precision, making it unsuitable for complex designs.

2. Chemical Method:

Applying a protective layer to a copper clad board and etching away unnecessary copper in a corrosive solution. This method is widely used and offers precision control.

Ways to Apply the Protective Layer:

- Manual painting

- Adhesive stickers

- Film photosensitive

- Thermal transfer

Users can choose between physical and chemical methods based on their needs. At Well Circuits, we offer flexible ordering options and free DFM reviews to ensure customer satisfaction.