Flexible Printed Circuit (FPC) Overview

Introduction

FPC, or Flexible Printed Circuit, also known as **柔性印刷电路板** or **软板** in Chinese, is created using light imaging pattern transfer and etching processes on a flexible substrate to form conductor circuit patterns. It provides electrical connections between the surface and inner layers of circuit boards through metallized holes, with a protective PI layer and adhesive.

Features of FPC

- Short: Reduces assembly time by pre-configuring all connections.

- Small: Compact size enhances portability.

- Light: Lightweight construction reduces the final product’s weight.

- Thin: Thinner than traditional PCBs, enhancing flexibility in assembly.

Advantages of Flexible Circuit Boards

FPCs offer several benefits over rigid PCBs:

- Flexibility: Can be bent, wound, and folded to meet spatial layout needs.

- Size and Weight Reduction: Ideal for high-density and miniaturized electronic devices.

- Improved Features: Enhanced heat dissipation, solderability, and cost-effectiveness.

Main Raw Materials for FPC

1. Substrate

The primary raw materials for substrates include copper foil, adhesive, and PI (polyimide).

1.1 Adhesive Substrate

Consists of copper foil, adhesive, and PI, available in single-sided and double-sided types.

1.2 Non-Adhesive Substrate

Comprising copper foil and PI, these substrates offer better dimensional stability and heat resistance.

Copper Foil: Available in various thicknesses to meet specific requirements.

2. Cover Film

Comprising release paper, adhesive, and PI, the cover film protects the product during production.

3. Reinforcement

Materials like FR4, steel sheet, and PI are used to enhance support strength in FPCs.

4. Other Auxiliary Materials

Pure Glue

A heat-curing acrylic adhesive film with protective paper/release film, used for bonding in layered boards, flexible and rigid boards, and FR-4/steel sheet reinforcement boards.

Electromagnetic Protective Film

Applied to the board surface for shielding.

Pure Copper Foil

Composed solely of copper foil, mainly used for hollow board production.

Types of FPC

- Single-Sided Panel: Wiring is present on only one side.

- Double-Sided Panel: Wiring is present on both sides.

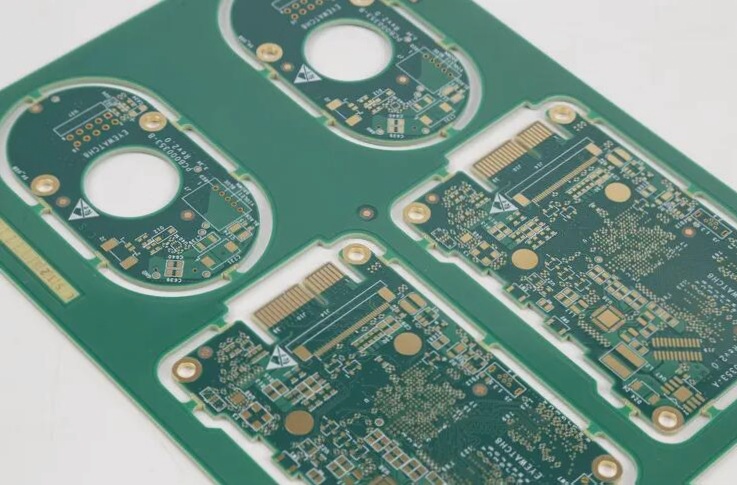

- Hollow Board: Also known as a window board, featuring an opening on one surface.

- Layered Board: A two-sided circuit with separate layers.

- Multilayer Board: Consists of more than two layers.

- Rigid-Flex Board: A combination of flexible and rigid boards.

Future Trends in FPC Development

FPCs are expected to evolve in three main areas:

- Thickness: Future FPCs must be even thinner and more flexible.

- Folding Resistance: Enhanced folding resistance will be a key feature for future FPCs.

- Process Level: To meet diverse requirements, FPC processes will need upgrading, with tighter specifications for minimum aperture and line width/spacing.