The Importance of Bill of Materials (BOM) in Hardware Engineering

A Bill of Materials (BOM) is a crucial document in hardware engineering that acts as a comprehensive list of all the components, parts, and materials necessary for the production of a product. It not only outlines what is needed but also provides guidance on sourcing and utilizing these elements. A well-structured BOM is vital for effective communication and the successful development of a product.

Key Insights from a Bill of Materials

- Lead time for material procurement

- Cost of Goods Sold (COGS)

- Manufacturing processes

- Design for Assembly quality

- Supply chain reliability

- Cash flow requirements

Components of an Effective Bill of Materials

An efficient BOM doesn’t necessarily require complex software; a simple Excel spreadsheet can suffice. However, it must be well-organized to cater to various stakeholders, including design teams, engineers, and manufacturing departments.

For a BOM to be truly effective, it should include detailed product data. Here are essential elements to incorporate:

- BOM Level — Numbering parts for hierarchy clarity

- Part Number — Unique identifiers for easy referencing

- Part Name — Clear names for better recognition

- Phase — Lifecycle stages for tracking progress

- Description — Detailed descriptions for clarity

- Quantity — Units required for assembly

- Unit of Measure — Measurement units for accuracy

- Procurement Type — Off-the-shelf or custom-made specification

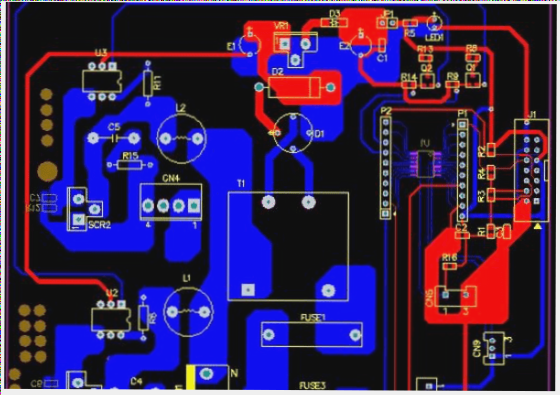

- Reference Designators — Location indicators for parts

- BOM Notes — Additional information for clarity

By including these details, your business operations and manufacturing processes can operate efficiently and effectively.

Approved Manufacturers for Components

Ensuring a proper factory setup involves listing approved manufacturers for each part in the AVL (Approved Vendor List). Manufacturers like TDK, Murata, and Panasonic should be specified, not just distributors like Digikey. This distinction is crucial for sourcing quality components and avoiding confusion in the production process.

The Importance of Specifying Electronic Components in Your BOM

When creating a Bill of Materials (BOM) for your PCB design, it is crucial to provide detailed specifications for each electronic component. Failure to do so can result in performance issues or even safety hazards. Here are some key considerations:

Manufacturer Matters

Choosing the right manufacturer for components like capacitors used in switching regulators is essential. Even if the rated capacitance and voltage are the same, using the wrong manufacturer can lead to instability or, in extreme cases, fires. On the other hand, for parts like pull-up resistors, leaving the manufacturer open can be acceptable, allowing the factory to suggest a preferred supplier.

Key Specifications for Components

- Resistors: Specify tolerance and wattage to avoid confusion between different types.

- Capacitors: Include tolerance, voltage rating, and dielectric type, especially for critical applications.

- Inductors: Fully specify parameters like core composition, DCR, saturation current, and temperature rise to ensure optimal circuit performance.

Consider Electronic Component Form Factor

- SMT Packages: Pay attention to component height, especially for larger packages, to ensure proper fit.

- Through-Hole Packages: Specify lead pitch and component height for accurate assembly.

- ICs: Use common package names for consistency and error reduction.

Importance of Extended Part Numbers

Abbreviated part numbers may cause confusion. Ensure complete part numbers include details like package type, manufacturer, and logic family to avoid errors in component selection.

Additional Tips for BOM Creation

- Include Consumables: Don’t forget items like glue, wires, and fasteners in your BOM to ensure smooth assembly.

- Attach Supporting Files: Associate CAD drawings and datasheets with BOM items for easy reference.

- Double-Check Information: Review your BOM thoroughly before submission to avoid costly mistakes.

- Track Changes: Implement a system to track BOM revisions and label versions clearly to prevent errors.

Tailoring Your BOM for Efficient PCB Manufacturing

- Customize Your BOM: Tailor your Bill of Materials to suit your project and partner companies’ requirements, ensuring it is organized and detailed accordingly.

- Utilize Templates: Many PCB manufacturers offer BOM templates that can simplify the quoting and ordering process, enhancing compatibility and reducing technical issues.

- Maintain Organization: Keep your BOM well-organized with all essential details included to avoid production delays and errors.

Ensuring your BOM is comprehensive and accurate is crucial for efficient PCB production processes.

Providing Detailed BOM Information

Include All Relevant Details: Your BOM should contain precise and clear information to guide PCB assembly accurately, especially for those unfamiliar with your project or language. While avoiding unnecessary details, strive for thoroughness as more detail generally leads to better outcomes.

An Accurate BOM Enhances Manufacturing Efficiency

Developing a detailed Bill of Materials is vital for translating your design into a physical product. Consider the end-users and how additional documentation like part datasheets and CAD files will be managed. Detailed part information can boost manufacturing efficiency and minimize mistakes.

Explore a Sample BOM

Here’s a snippet of a well-organized BOM sheet, providing a clear layout that is easy to navigate. While this example is simplified, your actual BOM will likely be more extensive and detailed.

In this BOM example, key details include the manufacturer’s name, part number, quantity, description with units, package type, and placement method. Wellcircuits’ services are also tailored to meet specific requirements.

At Wellcircuits, we offer top-quality PCB solutions, covering procurement, fabrication, and assembly. Simplify your PCB project with our comprehensive services and tools. Access our free resources or reach out to our expert support team for guidance at any project stage.

We provide instant online quoting, ordering, and reordering services. Submit your PCB assembly specifications, circuit files, and BOM easily through the provided button.

For any inquiries regarding PCBs or PCBA, contact us at info@wellcircuits.com.