PCB Components: Addressing Key Issues

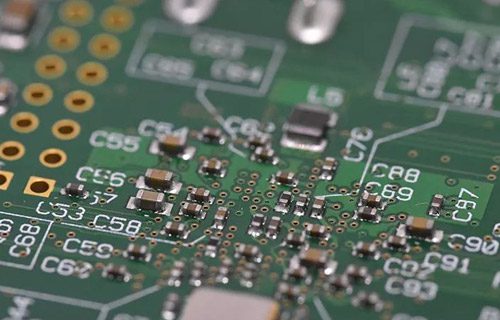

1. Addressing Problems in PCB Prototyping

- Limiting output current to prevent locking effect in CMOS circuits

- Implementing a filter network to reduce electromagnetic interference

- Forming an RC Network for sensitive inputs on bipolar devices

- Avoiding floating input pins on CMOS devices

Effective and reasonable use of components is crucial for stability and quality in PCB circuit board prototyping. To ensure a smooth process, these issues must be addressed.

2. Circuit Board Maintenance and Production

Circuit boards, also known as PCB boards, have various types including aluminum substrates, high-frequency boards, and thick copper boards. Understanding simple maintenance skills and the production process is essential.

Circuit Board Repair Skills: Observation Method

Repairing circuit boards using the observation method involves visually inspecting the board for burnt traces and other signs of damage.

- Determine manual damage by checking for deformations in corners and components.

- Inspect components like capacitors and resistors for signs of damage.

- Examine integrated circuits for issues like bulging or burning.