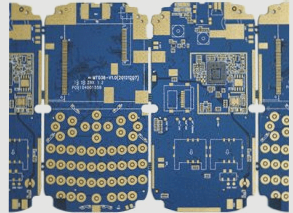

1. Physical damage to printed circuit board components is frequently a result of improper handling.

2. When we place the circuit board into the PCB assembly work area’s carrier, it may fall, collide, or be mishandled.

3. If laminated material sustains such damage, can it be repaired?

4. The answer to this question, like many in engineering, is situational.

5. Tips for repairing electronic circuit boards:

6. The industry standard “IPC-A-610: Acceptability of Electronic Components” provides a detailed classification of acceptable conditions for components and identifies defective components.

7. When minimum electrical clearance requirements are compromised, this specification categorizes broken corners or laminate damage as defects.

8. If a component is integral to the assembly or fails to meet customer printing specifications, it does not satisfy the requirements for “form, fit, or function.”

9. According to acceptance criteria, all aforementioned conditions are considered defects across all product types.

10. Furthermore, for all categories, exposed base metal due to corner damage will also be classified as a defect.

According to section 10.2.5 of the “IPC-A-610” standard, if the “crack” or corner damage exceeds half the distance of 2.5 mm (0.1 inch) or less from the edge of the PCB to the nearest conductor, it will also be classified as a defect.

Although the customer will ultimately define what constitutes a defect based on the industry standards mentioned above, once it is established that the damaged corner is indeed a defect, various disposal strategies may be employed. The options include using the circuit board as-is (with customer approval), repairing it (which involves physically addressing the damage), or discarding it. If the second option is chosen, the corners of the PCB will need to be repaired.

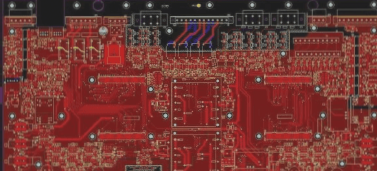

When a circuit board is physically damaged due to improper handling or if a component is dropped, resulting in damaged or missing corners, several additional inspections must be conducted on the component. In particular cases, especially when fragile solder alloys are involved, such as various lead-free alloys, the solder joints may fail due to physical impacts. Furthermore, parts near the corners may experience torn pads or traces. If the PCB is coated, the coating may have cracked following the drop. Lastly, the solder mask and the components themselves should be inspected, as they might also sustain damage from the impact.

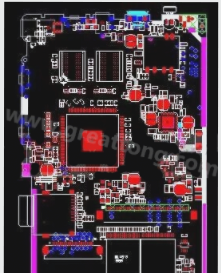

Numerous PCB repair methods are detailed in the PCB Repair Guide “IPC-7721: Rework, Modification and Repair of Electronic Components.” The first method involves repairing the laminate using epoxy resin. Typically, this method is employed for slightly damaged laminates. Another approach involves using regional or corner implants, which is applicable when the PCB laminate has sustained extensive damage or when the original material is no longer available, such as with broken corners. This method employs replacement laminates and utilizes a combination of grooves and tongues for repair.

This discussion emphasizes the epoxy method, which is commonly used to repair broken or damaged corners on assembled rigid PCBs. The initial step in this repair process is to assess the extent of the damage to the PCB. Begin by cleaning the area to be repaired to facilitate thorough inspection. Additionally, use the Gerber file set or conduct X-ray analysis to check for damage to the inner circuit wiring. If there is no damage to the internal layer or missing components due to PCB damage, the described repair method will suffice.

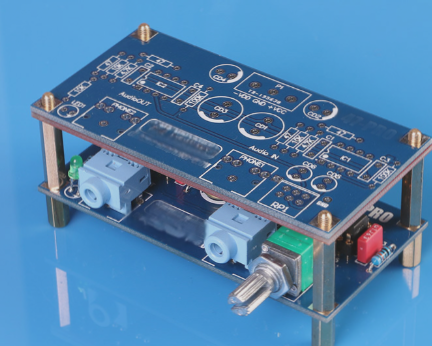

Use a ball mill to grind away any burrs or fibers from the laminate. If the damaged area is a significant corner, you can cut from the bottom to the edge of the laminate to enhance the bonding surface. If the internal circuit has been compromised, you will need to obtain approval or possess the necessary skills to carry out these repairs. Then, find a small plastic box to hold your small tools or nuts and bolts. This box is meant for single use, so if you can “borrow” one from somewhere, you can easily acquire a substitute laminate.

Next, mix the two components of the adhesive resin and hardener according to the PCB manufacturer’s instructions. Now, use a small container that has been modified to leave only one corner, positioning it at the corner to be repaired so that it aligns with the damaged area. Pour the epoxy resin mixture into this small container until the surface is smooth. The epoxy resin should cure according to the manufacturer’s guidelines. Use emery cloth along with some water to wet sand the adhesive. You may need to add additional epoxy or colorant to ensure that the shape, fit, and function of the repaired corners match the original design. The maintenance area should be cleaned and re-inspected according to acceptable standards.

By employing this epoxy resin method, you can effectively address the issue of damaged corners on the circuit board without relegating the affected PCB to the scrap pile.

2. When we place the circuit board into the PCB assembly work area’s carrier, it may fall, collide, or be mishandled.

3. If laminated material sustains such damage, can it be repaired?

4. The answer to this question, like many in engineering, is situational.

5. Tips for repairing electronic circuit boards:

6. The industry standard “IPC-A-610: Acceptability of Electronic Components” provides a detailed classification of acceptable conditions for components and identifies defective components.

7. When minimum electrical clearance requirements are compromised, this specification categorizes broken corners or laminate damage as defects.

8. If a component is integral to the assembly or fails to meet customer printing specifications, it does not satisfy the requirements for “form, fit, or function.”

9. According to acceptance criteria, all aforementioned conditions are considered defects across all product types.

10. Furthermore, for all categories, exposed base metal due to corner damage will also be classified as a defect.

According to section 10.2.5 of the “IPC-A-610” standard, if the “crack” or corner damage exceeds half the distance of 2.5 mm (0.1 inch) or less from the edge of the PCB to the nearest conductor, it will also be classified as a defect.

Although the customer will ultimately define what constitutes a defect based on the industry standards mentioned above, once it is established that the damaged corner is indeed a defect, various disposal strategies may be employed. The options include using the circuit board as-is (with customer approval), repairing it (which involves physically addressing the damage), or discarding it. If the second option is chosen, the corners of the PCB will need to be repaired.

When a circuit board is physically damaged due to improper handling or if a component is dropped, resulting in damaged or missing corners, several additional inspections must be conducted on the component. In particular cases, especially when fragile solder alloys are involved, such as various lead-free alloys, the solder joints may fail due to physical impacts. Furthermore, parts near the corners may experience torn pads or traces. If the PCB is coated, the coating may have cracked following the drop. Lastly, the solder mask and the components themselves should be inspected, as they might also sustain damage from the impact.

Numerous PCB repair methods are detailed in the PCB Repair Guide “IPC-7721: Rework, Modification and Repair of Electronic Components.” The first method involves repairing the laminate using epoxy resin. Typically, this method is employed for slightly damaged laminates. Another approach involves using regional or corner implants, which is applicable when the PCB laminate has sustained extensive damage or when the original material is no longer available, such as with broken corners. This method employs replacement laminates and utilizes a combination of grooves and tongues for repair.

This discussion emphasizes the epoxy method, which is commonly used to repair broken or damaged corners on assembled rigid PCBs. The initial step in this repair process is to assess the extent of the damage to the PCB. Begin by cleaning the area to be repaired to facilitate thorough inspection. Additionally, use the Gerber file set or conduct X-ray analysis to check for damage to the inner circuit wiring. If there is no damage to the internal layer or missing components due to PCB damage, the described repair method will suffice.

Use a ball mill to grind away any burrs or fibers from the laminate. If the damaged area is a significant corner, you can cut from the bottom to the edge of the laminate to enhance the bonding surface. If the internal circuit has been compromised, you will need to obtain approval or possess the necessary skills to carry out these repairs. Then, find a small plastic box to hold your small tools or nuts and bolts. This box is meant for single use, so if you can “borrow” one from somewhere, you can easily acquire a substitute laminate.

Next, mix the two components of the adhesive resin and hardener according to the PCB manufacturer’s instructions. Now, use a small container that has been modified to leave only one corner, positioning it at the corner to be repaired so that it aligns with the damaged area. Pour the epoxy resin mixture into this small container until the surface is smooth. The epoxy resin should cure according to the manufacturer’s guidelines. Use emery cloth along with some water to wet sand the adhesive. You may need to add additional epoxy or colorant to ensure that the shape, fit, and function of the repaired corners match the original design. The maintenance area should be cleaned and re-inspected according to acceptable standards.

By employing this epoxy resin method, you can effectively address the issue of damaged corners on the circuit board without relegating the affected PCB to the scrap pile.