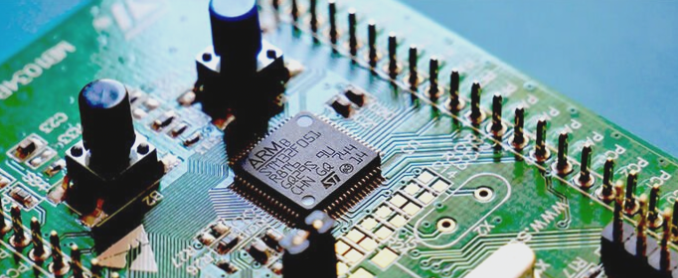

The Importance of High-Quality Soldering Materials in PCBA Component Attachment

When attaching components to a PCB, using high-quality solder is crucial for effective soldering. However, post-soldering, residues can form on the board surface, impacting both appearance and electrical performance.

Proper Cleaning Procedures for PCBA Components

It is essential to utilize a plate washer for thorough surface cleaning of PCBA components. Providing proper guidance and protective measures to staff ensures meeting customer requirements, reducing complaints, and preventing injuries.

PCBA Cleaning Operations:

- Utilize washing stations for maintenance cleaning.

Preparation Before Operation:

- Arrive early for shift meetings and self-inspection.

- Complete handover records and address identified issues.

- Wear protective gear like masks, gloves, and static rings.

Operation Process and Methods:

- Manual + Brush Cleaning Method:

- Scrub PCB with an anti-static brush dipped in washing water to remove tin slag and flux.

- Check for residues, wipe if necessary, and place the PCB on an electrostatic plate.

- Perform “5S” tasks at the workstation after completion.

- Brush Washer Cleaning Method:

- Immerse the plate in washer water, then brush to clean thoroughly.

- Cover the washer water to reduce volatilization after use.

Precautions for Plate Washing:

- Avoid washing sensitive components like speakers, sensors, and connectors to prevent damage.

- Be cautious with electrolytic capacitors and communication modules to avoid removing surface markings.

- Regularly clean the anti-static brush and inspect soldering positions for residues.

- Ensure barcode and silk screen integrity post-cleaning to identify defective products.

- Plate washing water is flammable and corrosive; wear protective gear and prioritize safety.