Flexible PCB Applications

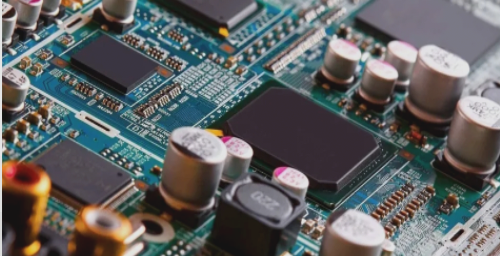

The demand for flexible circuit boards (PCBs) has been increasing due to the miniaturization of electronic products. Flexible PCBs are used in various applications, including:

- Installation of driver chips for flat-panel displays.

- Integration into smartphones, computer modules, and optical signal receivers.

Types of Flexible Copper Clad Laminate (CCL)

Flexible Copper Clad Laminate (CCL) comes in two main types:

- Three-layer structure with epoxy resin adhesive.

- Two-layer structure without adhesive, offering superior heat resistance and stability.

The lack of adhesive in the two-layer structure can pose challenges during PCB production.

Halogen-Free Coating Materials

Coating materials protect flexible PCB circuitry, ensuring longevity and reliability. New halogen-free coatings aim to address environmental concerns but may face challenges in insulation reliability and peel strength. Researchers are working on:

- Understanding the role of halogens in coatings.

- Ensuring halogen-free coatings provide sufficient insulation and peel strength.

- Maintaining coating softness and controlling fluidity for desired thickness.

Technology for Halogen-Free Solutions

Researchers are exploring various strategies to achieve flame retardancy in halogen-free coatings, including:

- Using phosphorus-based flame retardants for protective carbonized layers.

- Introducing nitrogen-containing flame retardants to reduce oxygen availability.

- Incorporating inorganic flame retardants to inhibit flame spread.

- Developing special resin structures for enhanced flame resistance.

Conclusion

Advanced surface treatment technologies for copper foil and pressing techniques for CCL have improved adhesion, leading to superior flexible CCL. New halogen-free coating materials offer both protection and flame retardancy, allowing for the production of fully halogen-free flexible PCBs.

Benefits of Halogen-Free PCBs

- 00:22 Understanding the concept of halogen-free

- 01:36 Exploring alternatives to halogen

- 02:24 Key advantages of choosing Halogen-Free PCBs

- 03:35 Addressing the limitations of Halogen-Free PCBs

Halogen-free PCBs have become increasingly popular as a response to growing environmental and safety concerns associated with traditional PCBs containing halogen elements like bromine and chlorine. The shift towards halogen-free PCBs is being primarily driven by the desire for electronic products that are not only more environmentally friendly but also less hazardous.

If you have any inquiries regarding PCB or PCBA, please don’t hesitate to reach out to us at info@wellcircuits.com.