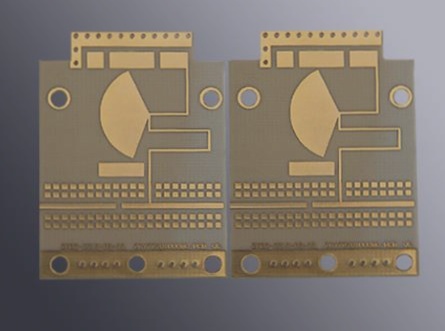

Flexible printed circuit boards (PCBs) incorporate highly sensitive components, necessitating careful handling to prevent damage. Even slight pressure on any part of a flexible PCB can result in significant harm, while minimal static electricity discharge can render the circuit board unusable. To mitigate these risks, it’s crucial to minimize static electricity generation, discharge accumulated static electricity, and handle flexible PCBs with utmost care.

Here are essential precautions for handling and storing flexible printed circuit boards:

1. **Proper Grounding:** Before handling a flexible PCB, it’s advisable to wear rubber-soled shoes to facilitate grounding, thus preventing static electricity buildup that could harm the circuit board. Additionally, always wear a grounded wrist strap when manipulating circuit board components.

2. **Metal Touching:** Prior to handling, touch a metal surface for at least two seconds to discharge any residual static electricity from your body.

3. **Humidity Control:** Maintain high humidity levels in the workspace to reduce static electricity buildup, particularly in dry environments where accumulation is more common.

4. **Avoid Static-Generating Materials:** Unless absolutely necessary, keep materials known to generate static electricity, such as plastic, fabric, vinyl, and polystyrene foam, away from flexible PCBs.

5. **Glove Usage:** Wear gloves when unpacking and handling flexible circuit boards. When removing the circuit board from its anti-static bag, ensure at least one edge touches the bag. Place the board directly on the bag and keep it there until ready for installation.

6. **Proper Installation:** When installing flexible circuit boards, apply the necessary pressure (avoid excessive force) to secure them into the correct module of the product or device. Avoid forcefully fixing components in place.

7. **Regular Inspection:** Regularly inspect designated workstations and storage areas for flexible circuit boards to ensure proper protection measures are in place. Areas of concern include static dissipation on work surfaces, correct grounding methods, and the functionality of ion blowers and air guns.

8. **Use of Shielding:** When not in use, enclose flexible circuit boards in shielding bags or boxes to protect them from electrostatic discharge (ESD). These protective housings come in three types: anti-static, electrostatic shielding, and static electricity dissipation materials.

9. **Avoid Silicone Lotions:** Refrain from using lotions and hand creams containing silicone, as they can lead to epoxy adhesion and solderability issues. Instead, use specially formulated emulsions to prevent contamination of flexible PCBs.

As a professional manufacturer of FPC soft boards, WellCircuits Limited is privileged to have collaborated with many clients. We are committed to assisting our new customers in any way possible. Please don’t hesitate to contact us with any inquiries.

Here are essential precautions for handling and storing flexible printed circuit boards:

1. **Proper Grounding:** Before handling a flexible PCB, it’s advisable to wear rubber-soled shoes to facilitate grounding, thus preventing static electricity buildup that could harm the circuit board. Additionally, always wear a grounded wrist strap when manipulating circuit board components.

2. **Metal Touching:** Prior to handling, touch a metal surface for at least two seconds to discharge any residual static electricity from your body.

3. **Humidity Control:** Maintain high humidity levels in the workspace to reduce static electricity buildup, particularly in dry environments where accumulation is more common.

4. **Avoid Static-Generating Materials:** Unless absolutely necessary, keep materials known to generate static electricity, such as plastic, fabric, vinyl, and polystyrene foam, away from flexible PCBs.

5. **Glove Usage:** Wear gloves when unpacking and handling flexible circuit boards. When removing the circuit board from its anti-static bag, ensure at least one edge touches the bag. Place the board directly on the bag and keep it there until ready for installation.

6. **Proper Installation:** When installing flexible circuit boards, apply the necessary pressure (avoid excessive force) to secure them into the correct module of the product or device. Avoid forcefully fixing components in place.

7. **Regular Inspection:** Regularly inspect designated workstations and storage areas for flexible circuit boards to ensure proper protection measures are in place. Areas of concern include static dissipation on work surfaces, correct grounding methods, and the functionality of ion blowers and air guns.

8. **Use of Shielding:** When not in use, enclose flexible circuit boards in shielding bags or boxes to protect them from electrostatic discharge (ESD). These protective housings come in three types: anti-static, electrostatic shielding, and static electricity dissipation materials.

9. **Avoid Silicone Lotions:** Refrain from using lotions and hand creams containing silicone, as they can lead to epoxy adhesion and solderability issues. Instead, use specially formulated emulsions to prevent contamination of flexible PCBs.

As a professional manufacturer of FPC soft boards, WellCircuits Limited is privileged to have collaborated with many clients. We are committed to assisting our new customers in any way possible. Please don’t hesitate to contact us with any inquiries.