1. Below, I will take an actual hardware design project as an example to discuss the basic principles and ideas of hardware development with you, and welcome your questions and opinions. To fully understand the design needs of all parties and determine appropriate solutions.

2. Start a hardware development project; the original impetus will come from many aspects, such as the need of the market, based on the needs of the overall system architecture, the realization of the function of the application software department needs, improve the ability to some aspect of need, and so on. So as hardware system designers, to actively understand all aspects of demand and together propose the most suitable hardware solution.

3. For example, the original driving force of Project A comes from a high-level software team inside the company. In practice, they found that the original IP forwarding capacity of the processor board could not meet the requirements, which would cause great inconvenience to the configuration and use of the system. Therefore, they proposed the demand for new hardware.

4. According to this goal, the hardware scheme pointed to chose two high-performance network processors. Then, further communication with software designers is needed to determine memory size, internal structure, external interfaces, debugging the number and type of the interface, and other details. For example, software people like to control signaling pathways and data paths to separate completely, so in determining the internal data, this needs to be considered.

5. At the beginning of the project, many discussion meetings are needed, and efforts should be made to invite all related departments to participate. There are three benefits: first, it can fully understand the needs to avoid missing important functions in system design. Second, it lets each department understand the project’s situation early, ready to collaborate on time and personnel. Third, involving each department in the design from the beginning makes the project a common brainchild, getting everybody’s care and good cooperation, which is very helpful to finish the work.

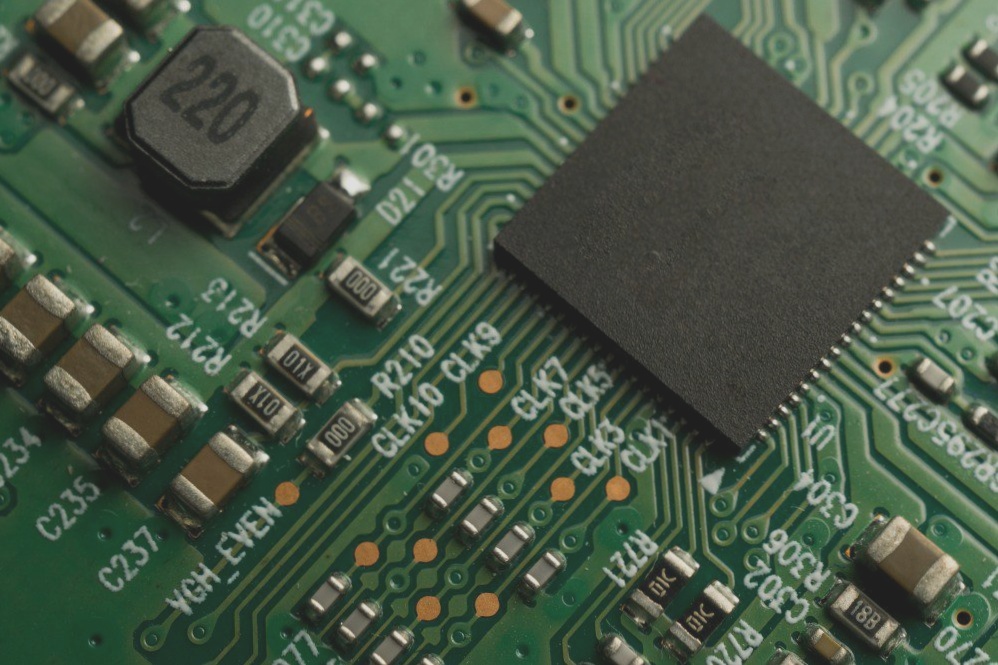

6. Schematic diagram design should pay attention to the problem. Schematic design should have a guiding principle. Chip manufacturers generally provide reference design schematics, so try to use these resources. On the basis of fully understanding the reference design, do some modifications.

7. When the main chip is selected, the most critical peripheral design includes power supply, clock, and interconnection between the chips. Power is essential to ensure the normal operation of the hardware system. The design requires detailed analysis: the system’s power input; the power output that the board needs to generate; the current size each power supply needs to provide; power supply circuit efficiency; the allowable fluctuation range of each power supply; power-on sequence required by the entire power system, etc.

8. For example, a network processor in the project requires a core voltage of 1.25 V, with a required accuracy between +5% and -3%, and will need about 12 A current. According to these requirements, in the design, a 5 V power input is used, along with Linear controller and IR MOSFET switch power supply structures. The appropriate power supply circuit is chosen, the accuracy requirement determines the output capacitance of the ESR choice, and a distal feedback function is added to prevent excessive current caused by voltage drop.

9. The clock circuit needs to meet the jitter requirements to achieve the goal. For example, a project involving GE PHY devices initially uses an internal phase lock loop zero delay for 100 MHz clock chip clock distribution, but this results in packet loss on the GE link. Later, a simple clock buffer device solves the problem of packet loss, as analysis revealed that internal PLL jitter is introduced.

10. The interconnection between chips should ensure the correct transmission of data. High-speed differential signal lines are adopted in the interconnection between multiple chips in Project A, and there are no problems in the debugging and testing.

11. In PCB design, the purpose should be clear. For important signal lines, strict requirements should be placed on the wiring length and processing ground loop. For low-speed and unimportant signal lines, the wiring priority should be slightly lower.

12. Important parts include power supply division; memory clock line, control line, and data line length requirements; high-speed differential line wiring, and so on. For example, a project using a 1 G DDR memory chip places critical importance on wiring, considering the topology of distribution line and address line, the length difference of data and clock lines, etc.

13. When these requirements are determined, the PCB designer can be clearly asked to achieve them. If all the important wiring requirements are clear in the design, the overall wiring constraints can be converted. The automatic wiring tool software in CAD can be used to achieve PCB design, which is also a development trend in high-speed PCB design.

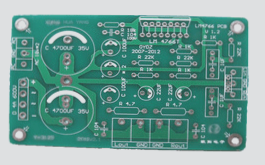

14. When ready to debug a board, thorough visual inspection must be carried out. Firstly, check for visible circuit welding problems and pin tin issues. Check for component model errors, misplacement of pins, assembly leakage, etc. Then use a multimeter to measure the power supply to ground resistance to check for short circuits. This good habit can avoid damaging the board after rushing to power it.

15. In the debugging process, maintain a calm state of mind, as encountering problems is normal. The approach should involve more comparison and analysis to gradually eliminate possible causes. Firmly believe that “everything has a solution” and “there must be a reason for the problem”, so that successful debugging can be achieved in the end.

16. Now, from a technical perspective, every design can be achieved. However, the success of a project depends not only on technical implementation but also on completing it on time, product quality, and the team’s close cooperation. Therefore, good team cooperation, transparent communication, careful research and development arrangements, and abundant materials and personnel arrangements are essential to ensure the success of a project.

17. A good hardware engineer is essentially a project manager. They need to communicate with the outside world to obtain the requirements of their design, summarize and analyze them into specific hardware implementations. They have to liaise with various chip and solution suppliers to select suitable solutions.

18. When the schematic is completed, they need to organize colleagues to review it and work with CAD engineers to complete the PCB design. Simultaneously, they should prepare the BOM list, start purchasing and preparing materials, and contact the processing factory to complete the board installation.

19. During debugging, they should organize software engineers to tackle key problems and cooperate with test engineers to solve issues found during testing. If there are problems after the products are launched, they should provide timely support.

20. Therefore, a hardware designer should possess good communication skills, the ability to adjust under pressure, coordination and decision-making abilities to handle multiple tasks simultaneously, as well as maintaining a calm state of mind. They should be careful and meticulous because a small oversight in hardware design can often lead to significant economic losses. For example, a mistake in PCB design once caused a power supply layer and stratum to be joined together, resulting in hundreds of thousands of losses. Hence, careful inspection, responsible testing, relentless learning, and accumulation are vital for continuous progress in hardware design.

2. Start a hardware development project; the original impetus will come from many aspects, such as the need of the market, based on the needs of the overall system architecture, the realization of the function of the application software department needs, improve the ability to some aspect of need, and so on. So as hardware system designers, to actively understand all aspects of demand and together propose the most suitable hardware solution.

3. For example, the original driving force of Project A comes from a high-level software team inside the company. In practice, they found that the original IP forwarding capacity of the processor board could not meet the requirements, which would cause great inconvenience to the configuration and use of the system. Therefore, they proposed the demand for new hardware.

4. According to this goal, the hardware scheme pointed to chose two high-performance network processors. Then, further communication with software designers is needed to determine memory size, internal structure, external interfaces, debugging the number and type of the interface, and other details. For example, software people like to control signaling pathways and data paths to separate completely, so in determining the internal data, this needs to be considered.

5. At the beginning of the project, many discussion meetings are needed, and efforts should be made to invite all related departments to participate. There are three benefits: first, it can fully understand the needs to avoid missing important functions in system design. Second, it lets each department understand the project’s situation early, ready to collaborate on time and personnel. Third, involving each department in the design from the beginning makes the project a common brainchild, getting everybody’s care and good cooperation, which is very helpful to finish the work.

6. Schematic diagram design should pay attention to the problem. Schematic design should have a guiding principle. Chip manufacturers generally provide reference design schematics, so try to use these resources. On the basis of fully understanding the reference design, do some modifications.

7. When the main chip is selected, the most critical peripheral design includes power supply, clock, and interconnection between the chips. Power is essential to ensure the normal operation of the hardware system. The design requires detailed analysis: the system’s power input; the power output that the board needs to generate; the current size each power supply needs to provide; power supply circuit efficiency; the allowable fluctuation range of each power supply; power-on sequence required by the entire power system, etc.

8. For example, a network processor in the project requires a core voltage of 1.25 V, with a required accuracy between +5% and -3%, and will need about 12 A current. According to these requirements, in the design, a 5 V power input is used, along with Linear controller and IR MOSFET switch power supply structures. The appropriate power supply circuit is chosen, the accuracy requirement determines the output capacitance of the ESR choice, and a distal feedback function is added to prevent excessive current caused by voltage drop.

9. The clock circuit needs to meet the jitter requirements to achieve the goal. For example, a project involving GE PHY devices initially uses an internal phase lock loop zero delay for 100 MHz clock chip clock distribution, but this results in packet loss on the GE link. Later, a simple clock buffer device solves the problem of packet loss, as analysis revealed that internal PLL jitter is introduced.

10. The interconnection between chips should ensure the correct transmission of data. High-speed differential signal lines are adopted in the interconnection between multiple chips in Project A, and there are no problems in the debugging and testing.

11. In PCB design, the purpose should be clear. For important signal lines, strict requirements should be placed on the wiring length and processing ground loop. For low-speed and unimportant signal lines, the wiring priority should be slightly lower.

12. Important parts include power supply division; memory clock line, control line, and data line length requirements; high-speed differential line wiring, and so on. For example, a project using a 1 G DDR memory chip places critical importance on wiring, considering the topology of distribution line and address line, the length difference of data and clock lines, etc.

13. When these requirements are determined, the PCB designer can be clearly asked to achieve them. If all the important wiring requirements are clear in the design, the overall wiring constraints can be converted. The automatic wiring tool software in CAD can be used to achieve PCB design, which is also a development trend in high-speed PCB design.

14. When ready to debug a board, thorough visual inspection must be carried out. Firstly, check for visible circuit welding problems and pin tin issues. Check for component model errors, misplacement of pins, assembly leakage, etc. Then use a multimeter to measure the power supply to ground resistance to check for short circuits. This good habit can avoid damaging the board after rushing to power it.

15. In the debugging process, maintain a calm state of mind, as encountering problems is normal. The approach should involve more comparison and analysis to gradually eliminate possible causes. Firmly believe that “everything has a solution” and “there must be a reason for the problem”, so that successful debugging can be achieved in the end.

16. Now, from a technical perspective, every design can be achieved. However, the success of a project depends not only on technical implementation but also on completing it on time, product quality, and the team’s close cooperation. Therefore, good team cooperation, transparent communication, careful research and development arrangements, and abundant materials and personnel arrangements are essential to ensure the success of a project.

17. A good hardware engineer is essentially a project manager. They need to communicate with the outside world to obtain the requirements of their design, summarize and analyze them into specific hardware implementations. They have to liaise with various chip and solution suppliers to select suitable solutions.

18. When the schematic is completed, they need to organize colleagues to review it and work with CAD engineers to complete the PCB design. Simultaneously, they should prepare the BOM list, start purchasing and preparing materials, and contact the processing factory to complete the board installation.

19. During debugging, they should organize software engineers to tackle key problems and cooperate with test engineers to solve issues found during testing. If there are problems after the products are launched, they should provide timely support.

20. Therefore, a hardware designer should possess good communication skills, the ability to adjust under pressure, coordination and decision-making abilities to handle multiple tasks simultaneously, as well as maintaining a calm state of mind. They should be careful and meticulous because a small oversight in hardware design can often lead to significant economic losses. For example, a mistake in PCB design once caused a power supply layer and stratum to be joined together, resulting in hundreds of thousands of losses. Hence, careful inspection, responsible testing, relentless learning, and accumulation are vital for continuous progress in hardware design.