HASL involves coating PCBs with a layer of eutectic solder, primarily used as a post-processing technique in circuit board manufacturing. This process combines immersion soldering with HASL to achieve uniform solder coatings in the metalized holes of PCBs and on printed wires. Initially, the PCB is fluxed and then dipped into molten solder. Subsequently, it passes through two air knives where excess solder is blown off using hot compressed air. This step not only removes excess solder but also ensures a glossy, flat, and even coating, particularly in the metal holes.

One of the key advantages of HASL is its ability to maintain consistent coating composition throughout the process. It effectively protects the edges of the PCB and allows precise control over coating thickness using the air knives. The resulting bond between the coating and the base copper exhibits excellent wettability, weldability, and corrosion resistance. Given its role as a critical post-process for PCBs, the quality of HASL directly influences the PCB’s appearance, corrosion resistance, and soldering quality, which are paramount for customer satisfaction.

Effective control of the HASL process is therefore a significant concern for PCB manufacturers. The following section discusses experiences in controlling this process, focusing on vertical HASL, which is widely adopted in the industry.

Selection and Application of Flux

1. The flux used in Hot Air Solder Level (HASL) is specialized for its role in activating exposed copper surfaces on PCBs, enhancing solder wettability, and ensuring the laminate’s surface is not overheated. It also shields solder from oxidation during cooling, prevents solder resist coating adherence, and minimizes solder bridging between pads. Waste flux effectively cleans solder surfaces and removes solder oxides.

2. Essential Characteristics of Hot Air Solder Level Flux

– **Water Solubility and Environmental Compatibility**: Flux must be biodegradable, non-toxic, and water-soluble. This ensures easy cleaning with minimal residue, prevents ion pollution on PCB surfaces, and complies with environmental standards.

– **Activity**: Flux should effectively remove oxide layers from copper surfaces while improving solder wetting. Select fluxes with high activity that minimize copper solubility in solder, thereby reducing equipment damage due to smoke. Activity also impacts the brightness and evenness of the tin surface.

– **Thermal Stability**: It must protect the PCB’s green oil and substrate from thermal impact.

– **Viscosity**: Flux should possess adequate viscosity to ensure proper fluidity and prevent excessive adherence, especially in dense areas such as ICs, which can cause bridging.

– **Suitable Acidity**: Flux acidity should be balanced to prevent premature peeling of solder resist layers and minimize post-spray residue that could lead to tin surface blackening and oxidation.

3. Additional Considerations:

– Manufacturers should evaluate other factors such as odor, volatility, and operational costs, and conduct experiments to optimize performance.

Control and Selection of Hot Air Solder Level Process Parameters

1. **Tin Dipping Time**: Optimal immersion duration (2-4 seconds) ensures quality solder coating without damaging PCB materials or causing surface roughness.

2. **Bath Temperature**: Maintaining solder temperature between 232°C to 250°C balances intermetallic compound formation with PCB protection from heat damage.

3. **Air Knife Pressure**: Adjusting pressure (0.3-0.5 MPa) controls solder thickness post-immersion, ensuring clear metallization holes without compromising component integrity.

4. **Air Knife Temperature**: Temperature adjustments (300°C – 400°C) influence solder coating appearance post-leveling, preventing surface darkening below 176°C and optimizing flatness.

5. **Blade Spacing**: Proper spacing (0.95-1.25 cm) between air knives regulates airflow velocity to achieve optimal leveling force without damaging PCB surfaces.

6. **Blade Angle**: Adjusting angles (typically 4 degrees downward) ensures uniform solder thickness across PCBs, preventing molten solder splatter and noise.

7. **Rising Speed of PCB**: Conveyor speed influences solder thickness; slower speeds minimize solder accumulation, while faster speeds prevent hole blockage.

8. **Preheating Temperature and Time**: Preheating at 343°C for 15 seconds enhances flux activity, reducing thermal shock and improving overall soldering quality.

By meticulously controlling these parameters, PCB manufacturers optimize Hot Air Solder Level processes to ensure high-quality solder coatings and minimal environmental impact.

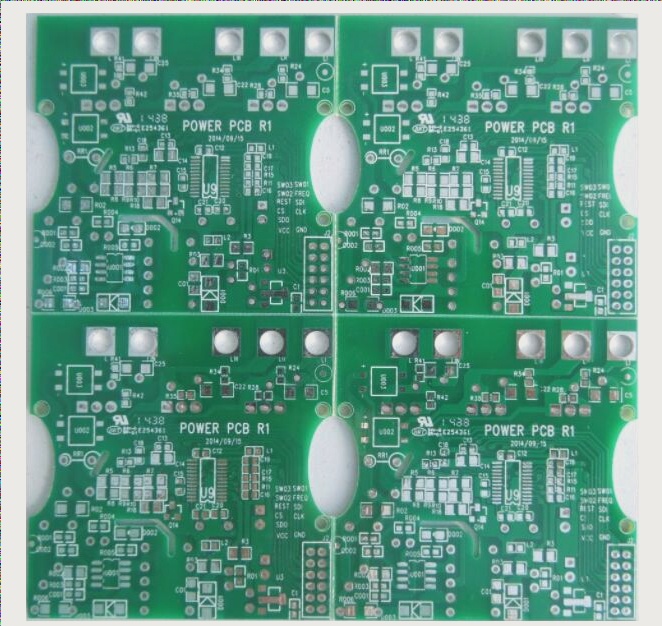

Uniformity of Solder Coating Thickness

1. The solder thickness applied to Hot Air Solder Level (HASL) is generally uniform. However, variations in the geometric factors of printed wires affect the air knife’s leveling effect on the solder, leading to fluctuations in solder coating thickness. Typically, wires parallel to the leveling direction encounter less air resistance and undergo greater leveling force, resulting in thinner coatings. Conversely, wires perpendicular to the leveling direction experience more air resistance and less leveling effect, leading to thicker coatings. This variability extends to solder coating within metallized holes. Due to the dynamic conditions of high pressure and temperature immediately post-tinning, achieving a completely uniform and flat tin surface is challenging but can be optimized through parameter adjustments.

2. Selection of Active Flux and Solder

Flux is pivotal for achieving a flat tin surface. Opting for a high-quality active flux promotes a relatively flat, bright, and complete tin surface. Solder should consist of high-purity lead-tin alloy, with regular copper floating treatments to maintain copper content below 0.03%. Detailed recommendations can be based on workload and test outcomes.

3. Equipment Adjustment

The air knife directly influences tin surface flatness. Parameters such as air knife angle, front and rear pressure differentials, temperature, spacing (both vertical and horizontal), and lifting speed significantly impact surface quality. Parameter values vary with different board types; advanced tin spraying machines often feature computer-stored parameters for automatic adjustments. Regular cleaning of air knives and guide rails, with residue clearance every two hours during heavy production, is essential.

4. Pretreatment

Micro-etching treatment profoundly affects tin surface flatness. Insufficient etching depth impedes copper-tin compound formation, resulting in local surface roughness. Inadequate stabilizer in the etching solution can cause uneven copper etching and tin surface irregularities. The APS system is typically recommended. Some board types may require baking plate pretreatment, which influences tin leveling.

5. Pre-process Control

As HASL is the final treatment, preceding processes significantly impact its outcome. For instance, unclean development can lead to poor tin loading. Strengthening control over prior processes effectively mitigates issues encountered during HASL. Despite potential variations in solder coating thickness, HASL typically complies with mil-std-275d requirements.