1. Concept

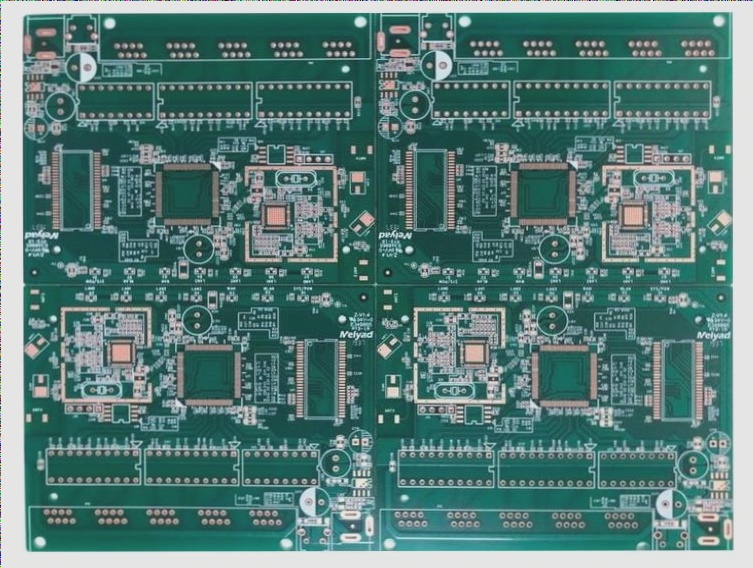

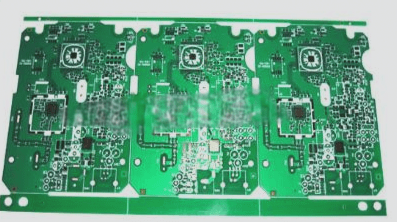

HDI: High-Density Interconnection Technology. It is a multilayer board produced using the build-up method and featuring micro-blind and buried vias.

Micro-holes: In a PCB, holes with a diameter less than 6 mil (150 µm) are termed micro-holes.

Buried Via Hole: A Buried Via Hole is an internal hole not visible in the finished board. It is used to connect inner layer circuits, minimizing signal interference and maintaining the characteristic impedance of the transmission line. Since buried vias do not occupy the PCB’s surface area, they allow for more surface-mounted components.

Blind Via: A Blind Via is a via hole that connects the surface layer to an inner layer but does not extend through the entire board.

2. Process Flow

High-density interconnection technology can currently be categorized into three levels of processes: the first-order process, which is 1+N+1; the second-order process, which is 2+N+2; and the third-order process, which is 3+N+3.

HDI: High-Density Interconnection Technology. It is a multilayer board produced using the build-up method and featuring micro-blind and buried vias.

Micro-holes: In a PCB, holes with a diameter less than 6 mil (150 µm) are termed micro-holes.

Buried Via Hole: A Buried Via Hole is an internal hole not visible in the finished board. It is used to connect inner layer circuits, minimizing signal interference and maintaining the characteristic impedance of the transmission line. Since buried vias do not occupy the PCB’s surface area, they allow for more surface-mounted components.

Blind Via: A Blind Via is a via hole that connects the surface layer to an inner layer but does not extend through the entire board.

2. Process Flow

High-density interconnection technology can currently be categorized into three levels of processes: the first-order process, which is 1+N+1; the second-order process, which is 2+N+2; and the third-order process, which is 3+N+3.