Revolutionizing PCB Technology: From Manual Wiring to Advanced Assembly Methods

PCB boards have transformed the electronics industry by allowing engineers to create intricate electronic systems quickly and cost-effectively. The evolution of design software has played a crucial role in streamlining the PCB manufacturing process.

Advancements in PCB Design

- Design engineers now have the capability to reduce part size, support SM and BGA packages, and decrease PCB line width and size.

- X-ray imaging has enhanced card inspection processes.

- The integration of AI in design software has automated certain tasks while maintaining manual control over critical functions like component placement.

The Changing Landscape of Component Placement

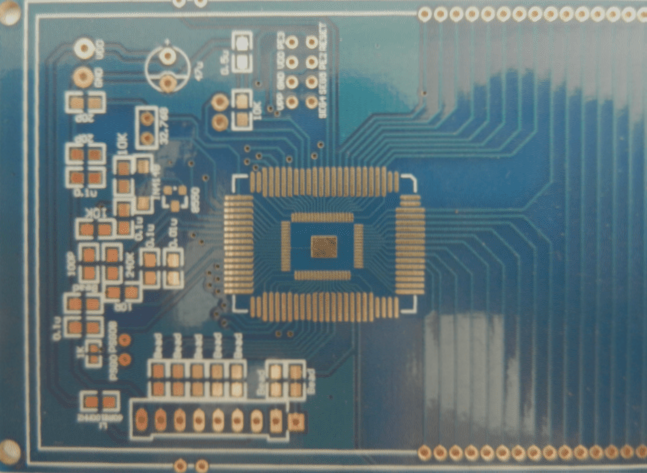

As design engineers progress in their careers, they transition from working on low-density circuit boards to handling high-density PCBs with tiny components like SMT, BGA, and QFN parts. This shift introduces new challenges in component placement and soldering processes.

Assembly Techniques

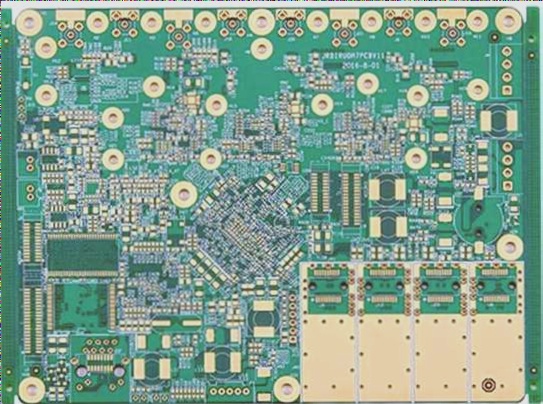

Design engineers must consider various assembly methods, including machine assembly, manual assembly, and hybrid assembly, based on factors such as cost, time, volume, and design complexity.

Exploring Assembly Methods

- Machine Assembly: Ideal for high-volume production, machine assembly follows strict design rules and minimizes re-engineering needs.

- Manual Assembly: While labor-intensive, manual assembly allows for flexibility in handling design rule exceptions and intricate soldering tasks.

- Hybrid Assembly: Combining manual component placement with infrared oven or wave soldering processes, hybrid assembly methods offer a balance between precision and efficiency.

Optimizing DFA Process

Understanding and optimizing the Design for Assembly (DFA) process is crucial for aligning PCB production with assembly methods. Each assembly technique has its unique benefits and considerations, impacting the overall manufacturing process.

Component Placement in High-Density PCB Board Design

The demand for high-density PCB boards introduces new challenges not present in sparse designs. In high-density design, it’s crucial to follow traditional design practices. A common issue is discarding reference codes, which increases density but is necessary for assembly. Engineers must create additional documentation to assist assembly technicians if these indicators are removed. Remember, PCB boards, schematics, and programs require significant human effort to develop before becoming functional, so thorough documentation is essential for others to work with your design. Always consider how your design choices will impact those who interact with your work after you. The next person might not pay dearly for your mistakes, but someone on the design and assembly team will have to convert your PCB board into a fully operational electronic system, making your vision a reality.

Latest Updates:

- If errors such as vertical lift occur during oven soldering, hybrid assemblers must ensure sufficient space between components for manual adjustment and rework.

- QA technicians may also be involved in the line.