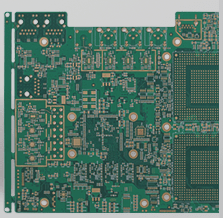

1. HDI circuit boards, or High-Density Interconnect circuit boards, encompass microvias (Microvia) with apertures below 6 mil, hole ring diameters (HolePad) below 0.25 mm, and a contact density exceeding 130 points per square inch. Additionally, they feature wiring densities surpassing 117 inches per square inch, with line width/spacing falling below 3 mil/3 mil.

2. In general, HDI circuit boards offer several advantages:

HDI technology is pivotal in most of today’s cutting-edge modern technologies. The miniaturization of digital components, facilitated by PCBs, has enabled manufacturers to produce smaller, more cost-efficient devices without compromising performance or reliability. Here are some key sectors that leverage HDI PCBs and how they utilize them:

1. **Consumer Electronics**: Gone are the days when computers occupied entire rooms. Thanks in part to HDI technology, devices as small as smartwatches function essentially as miniature computers. HDI boards are ubiquitous in laptops, smartphones, tablets, wearables, digital cameras, GPS devices, and other consumer electronics. They play a crucial role in granting everyday consumers access to these powerful technologies. Moreover, they are integral to IoT devices for the home, including smart thermostats, refrigerators, and various other connected gadgets. As the prevalence of these smart devices increases, so does the demand for HDI boards.

2. **Communications**: In addition to smartphones and laptops, HDI PCBs are found in the infrastructure that enables the functioning of these devices, such as routers, switches, components, and semiconductors. Anytime electronic communications, digital devices, or radio wave-utilizing devices are employed, there’s a high likelihood that an HDI board is involved. Digital video and audio equipment also frequently leverage HDI technology, being present in devices used for personal communication as well as the networks utilized by businesses.

3. **Automotive and Aerospace**: HDI PCBs allow manufacturers to incorporate more capabilities into smaller spaces and lighter-weight devices. This is particularly advantageous in the automotive and aerospace industries, where reduced weight can translate to more efficient operation. Much like other sectors, automobiles are becoming increasingly connected and computerized. Modern cars boast around 50 microprocessors onboard, contributing to engine controls, diagnostics, safety features, and other functionalities. Numerous new features, such as onboard WiFi, GPS, rearview cameras, and backup sensors, rely on HDI PCBs. As automotive technology continues to evolve, HDI technology is poised to play an even more significant role.

4. **Medical Industry**: Advanced digital medical devices, including certain monitoring equipment, imaging devices, surgical instruments, laboratory analysis tools, and other applications, may incorporate HDI boards. The high-density technology facilitates enhanced performance and smaller, more cost-effective devices, potentially improving the accuracy of monitoring and medical testing.

5. **Industrial Automation**: Industrial machinery is increasingly digitized, with IoT devices becoming more prevalent in manufacturing, warehousing, and other industrial settings. Much of this advanced equipment utilizes HDI technology. Nowadays, businesses employ digital tools for inventory tracking and equipment monitoring. Moreover, machinery increasingly incorporates smart sensors that collect usage data and connect to the internet to communicate with other smart devices, as well as relay information to management to optimize operations.

2. In general, HDI circuit boards offer several advantages:

HDI technology is pivotal in most of today’s cutting-edge modern technologies. The miniaturization of digital components, facilitated by PCBs, has enabled manufacturers to produce smaller, more cost-efficient devices without compromising performance or reliability. Here are some key sectors that leverage HDI PCBs and how they utilize them:

1. **Consumer Electronics**: Gone are the days when computers occupied entire rooms. Thanks in part to HDI technology, devices as small as smartwatches function essentially as miniature computers. HDI boards are ubiquitous in laptops, smartphones, tablets, wearables, digital cameras, GPS devices, and other consumer electronics. They play a crucial role in granting everyday consumers access to these powerful technologies. Moreover, they are integral to IoT devices for the home, including smart thermostats, refrigerators, and various other connected gadgets. As the prevalence of these smart devices increases, so does the demand for HDI boards.

2. **Communications**: In addition to smartphones and laptops, HDI PCBs are found in the infrastructure that enables the functioning of these devices, such as routers, switches, components, and semiconductors. Anytime electronic communications, digital devices, or radio wave-utilizing devices are employed, there’s a high likelihood that an HDI board is involved. Digital video and audio equipment also frequently leverage HDI technology, being present in devices used for personal communication as well as the networks utilized by businesses.

3. **Automotive and Aerospace**: HDI PCBs allow manufacturers to incorporate more capabilities into smaller spaces and lighter-weight devices. This is particularly advantageous in the automotive and aerospace industries, where reduced weight can translate to more efficient operation. Much like other sectors, automobiles are becoming increasingly connected and computerized. Modern cars boast around 50 microprocessors onboard, contributing to engine controls, diagnostics, safety features, and other functionalities. Numerous new features, such as onboard WiFi, GPS, rearview cameras, and backup sensors, rely on HDI PCBs. As automotive technology continues to evolve, HDI technology is poised to play an even more significant role.

4. **Medical Industry**: Advanced digital medical devices, including certain monitoring equipment, imaging devices, surgical instruments, laboratory analysis tools, and other applications, may incorporate HDI boards. The high-density technology facilitates enhanced performance and smaller, more cost-effective devices, potentially improving the accuracy of monitoring and medical testing.

5. **Industrial Automation**: Industrial machinery is increasingly digitized, with IoT devices becoming more prevalent in manufacturing, warehousing, and other industrial settings. Much of this advanced equipment utilizes HDI technology. Nowadays, businesses employ digital tools for inventory tracking and equipment monitoring. Moreover, machinery increasingly incorporates smart sensors that collect usage data and connect to the internet to communicate with other smart devices, as well as relay information to management to optimize operations.