Insights on PCB Circuit Board Maintenance

PCB Applications and Maintenance in China

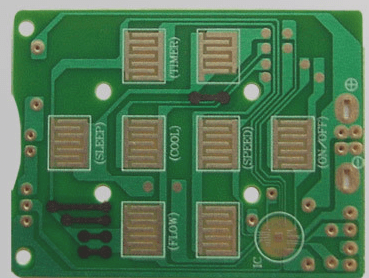

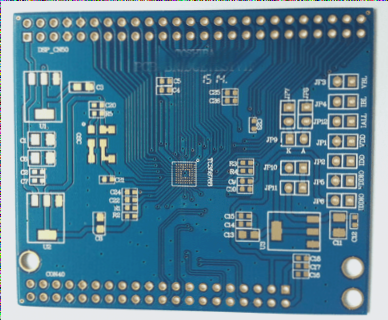

With the increasing use of PCB circuit boards in various electronic devices, maintenance has become crucial. In China, PCB applications span multiple sectors, leading to common faults in circuit boards as product usage rises. While replacing faulty PCBs can be costly, maintenance is a more cost-effective option, typically costing only 20%-30% of new boards.

Steps for PCB Circuit Board Maintenance

Step 1: Circuit Board Inspection

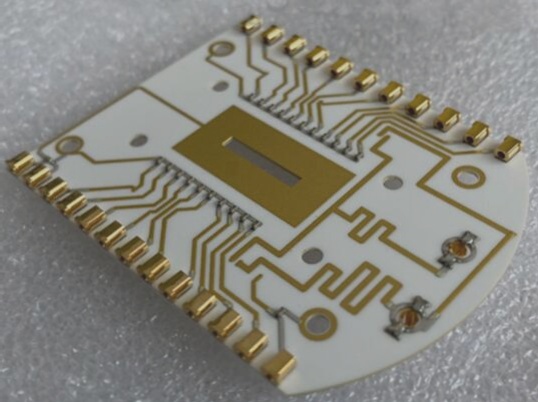

When common circuit board failures occur, users often lack design drawings. To address this, maintenance personnel conduct inspections to identify the root cause of the problem, typically related to components like field-effect transistors, resistors, and capacitors.

Step 2: Component Replacement

After identifying faults, engineers recommend replacing parts that meet application standards. Users can choose and replace parts according to their needs.

Step 3: On Board Operation Inspection

After repair, it’s crucial to evaluate success. Maintenance technicians should continuously improve standards throughout the maintenance process. Transitioning from known to unknown fault states is key, simplifying the repair process.