Designing a board that will be hand assembled.

It is a 12V power switching board and will see currents as high as 30A. Frequency is very low (quasi static, so no dynamic issues).

I’m using big polygon floods for the high current traces. I’m not certain they’ll be enough, but the traces are short, so <shrug> and hope for the best. Calculators suggest it’s iffy.

I’m debating whether I should enable thermal relief on the pins on the high current traces. On the one hand, IR heating in the spoke, on the other hand, a huge pain to solder.

What’s the received wisdom?

If it were wave soldered, this would be an easy decision. I have another version of this board that I have not tested at 30A, but it did have the direct connections, and it was indeed very difficult to solder the high current pins.

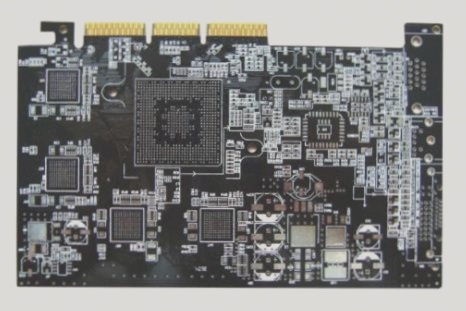

Picture attached. Q201 and Q202 are low Rdson Pfets. F2 is an automotive type fuse holder. J1 is vertically stacked Anderson Power Pole connectors. The drawing is a bit weird, but the long slots are the connections for J1.

Thanks in advance!