1. Since entering the 5G era, mobile phones have been evolving towards lighter, thinner, and multifunctional designs.

2. The internal integration of mobile phones is extensive, and the demands for mobile phone connectors have also escalated.

3. The FPC connector is characterized by its high flexibility, compact spacing, and low profile, making it ideally suited to the developmental needs of mobile devices.

4. Due to the advantages of FPC connectors in establishing connections, they have become essential components in electronic devices, including mobile phones.

5. The production process for mobile phone FPC connectors is comprehensive.

6. From pre-production to final shipment, each stage must be executed with precision, particularly in selecting suitable modules during testing.

7. The BTB/FPC high-current shrapnel micro-needle module offers an excellent solution for testing mobile phone FPC connectors.

8. The FPC connector has significant market development potential, featuring a slim profile and high-frequency signal transmission capabilities.

9. The pitch value has progressed from 0.5mm to 0.3mm or even smaller.

10. The rapid surge in 5G mobile phone production will lead to a substantial increase in demand for FPC connectors.

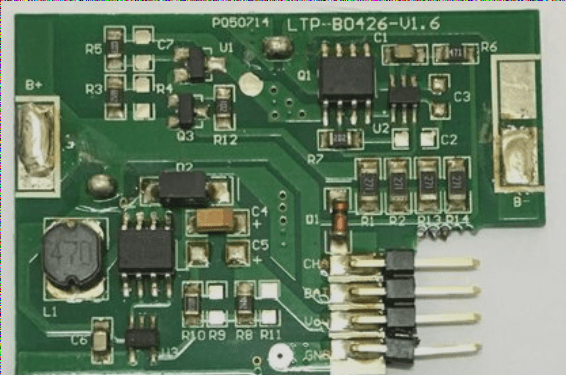

11. The components of an FPC connector include a rubber core, tongue piece, terminal, and welding piece.

12. Each component plays a specific role and collaborates to ensure high-speed connections.

In mobile phone FPC connector testing, the connection module must accommodate small pitches while providing excellent electrical conductivity to ensure a stable connection without disruptions. The BTB/FPC high-current shrapnel microneedle modules offer reliable solutions that enhance testing efficiency for FPC connectors and help reduce production costs for enterprises.

1. The BTB/FPC high-current shrapnel microneedle module features high-precision modularity with an integrated shrapnel structure that is lightweight, thin, and robust. In small pitch applications, it can adapt to a minimum pitch of 0.15mm. During FPC connector tests, stable connections are achieved between 0.15mm and 0.4mm, preventing issues such as broken or stuck pins, thus ensuring safety and reliability.

2. Regarding conductivity, the BTB/FPC high-current shrapnel microneedle module supports high current transmission, handling currents up to 50A. During operation, the current flows through the same material body without experiencing attenuation, ensuring consistent connection quality and resistance.

3. The BTB/FPC high-current shrapnel microneedle module boasts an average lifespan exceeding 20,000 cycles and maintains excellent performance even in complex testing environments. Its unique one-piece design features a self-cleaning shrapnel head, preventing contamination from impurities during tests.

These characteristics of the BTB/FPC high-current shrapnel microneedle module highlight its ability to maintain stable connections, transmit high currents, accommodate small pitches, and offer quick shipping and customization options. Overall, it delivers outstanding performance and cost-effectiveness.

2. The internal integration of mobile phones is extensive, and the demands for mobile phone connectors have also escalated.

3. The FPC connector is characterized by its high flexibility, compact spacing, and low profile, making it ideally suited to the developmental needs of mobile devices.

4. Due to the advantages of FPC connectors in establishing connections, they have become essential components in electronic devices, including mobile phones.

5. The production process for mobile phone FPC connectors is comprehensive.

6. From pre-production to final shipment, each stage must be executed with precision, particularly in selecting suitable modules during testing.

7. The BTB/FPC high-current shrapnel micro-needle module offers an excellent solution for testing mobile phone FPC connectors.

8. The FPC connector has significant market development potential, featuring a slim profile and high-frequency signal transmission capabilities.

9. The pitch value has progressed from 0.5mm to 0.3mm or even smaller.

10. The rapid surge in 5G mobile phone production will lead to a substantial increase in demand for FPC connectors.

11. The components of an FPC connector include a rubber core, tongue piece, terminal, and welding piece.

12. Each component plays a specific role and collaborates to ensure high-speed connections.

In mobile phone FPC connector testing, the connection module must accommodate small pitches while providing excellent electrical conductivity to ensure a stable connection without disruptions. The BTB/FPC high-current shrapnel microneedle modules offer reliable solutions that enhance testing efficiency for FPC connectors and help reduce production costs for enterprises.

1. The BTB/FPC high-current shrapnel microneedle module features high-precision modularity with an integrated shrapnel structure that is lightweight, thin, and robust. In small pitch applications, it can adapt to a minimum pitch of 0.15mm. During FPC connector tests, stable connections are achieved between 0.15mm and 0.4mm, preventing issues such as broken or stuck pins, thus ensuring safety and reliability.

2. Regarding conductivity, the BTB/FPC high-current shrapnel microneedle module supports high current transmission, handling currents up to 50A. During operation, the current flows through the same material body without experiencing attenuation, ensuring consistent connection quality and resistance.

3. The BTB/FPC high-current shrapnel microneedle module boasts an average lifespan exceeding 20,000 cycles and maintains excellent performance even in complex testing environments. Its unique one-piece design features a self-cleaning shrapnel head, preventing contamination from impurities during tests.

These characteristics of the BTB/FPC high-current shrapnel microneedle module highlight its ability to maintain stable connections, transmit high currents, accommodate small pitches, and offer quick shipping and customization options. Overall, it delivers outstanding performance and cost-effectiveness.