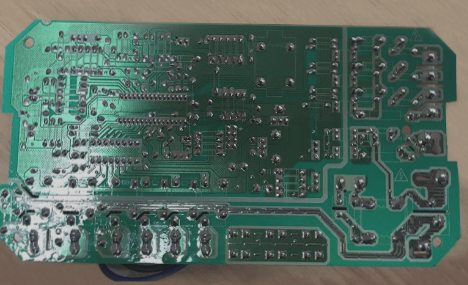

Challenges in Processing High-Frequency Microwave Boards

-

Drilling:

When working with PTFE boards, it is crucial to use specific methods for drilling to avoid wastage. The soft base material requires a slower speed and the use of new drills with special characteristics.

-

Printed Solder Mask:

After etching the board, avoid using a roller brush before printing the solder mask to prevent substrate damage. Chemical methods are recommended for surface treatment to ensure uniformity.

-

Hot Air Leveling:

Due to the properties of fluororesin, rapid heating should be avoided. Preheating at 150°C for 30 minutes before spraying tin is advised to maintain proper adhesion.

-

Milling Shape:

Special milling cutters are needed for milling fluorine resin to avoid burrs and ensure a flat surface.

-

Transportation:

During processing, boards should be transported flat with paper to prevent scratches and dents that can affect signal transmission.

-

Etching:

Control side erosion and line width tolerance to ±0.2mm to maintain quality. Use a 100x magnifying glass for inspection.

-

Electroless Copper Deposition:

Pretreatment methods like chemical or plasma are essential for stable quality. Plasma method requires expensive equipment but offers uniform results.

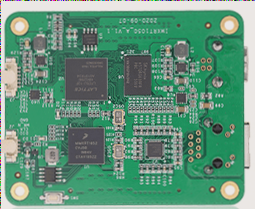

High-Frequency Substrates

For high-frequency substrates like ε3.38 and Rogers RO4003, which have similar performance to PTFE but are easier to process, using glass fiber and ceramics as filling materials is recommended. These substrates do not require special hole treatment and have been widely accepted by PCB manufacturers and customers.

However, it’s essential to note that RO4003 lacks flame retardant properties, and at 371℃, it can lead to burning of the board.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย