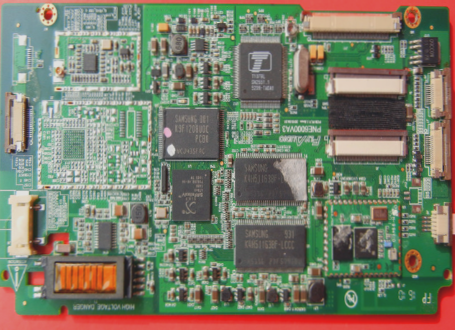

Power Supply Noise Impact on High-Frequency Signals in PCBs

Why Clean Power and Ground are Crucial

Power supply noise significantly affects high-frequency signals in PCBs. Clean power and ground are essential to minimize noise interference. The power supply exhibits distributed impedance, allowing noise to superimpose on the supply. To reduce power supply impedance, dedicated power supply layers and ground planes are necessary.

Ways to Eliminate Power Supply Noise in PCB Design

- Pay attention to through holes on the board to avoid signal detours and crosstalk.

- Ensure sufficient ground wires for connection lines to minimize loop area.

- Separate analog and digital power supplies to reduce digital noise interference.

- Avoid overlap of separate power supplies between layers to prevent circuit noise coupling.

- Isolate sensitive components like PLLs to prevent interference.

- Strategically place power cables alongside signal cables to reduce noise.

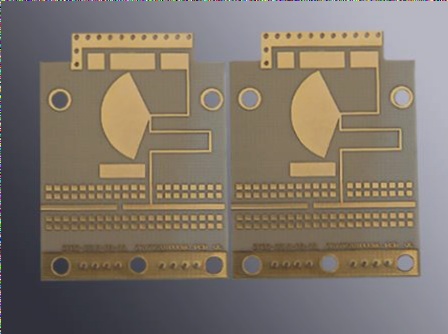

Transmission Lines in PCBs

PCBs feature strip lines and microwave lines, prone to signal reflection issues. Reflections complicate signal analysis and degrade signal quality. Impedance matching is crucial to mitigate these effects.

Methods to Eliminate Transmission Line Interference

- Avoid impedance discontinuities that disrupt transmission line integrity.

- Use angled traces over sharp corners and minimize vias.

- Segregate signal paths between PCB layers to reduce interference.

- Avoid stub lines to prevent noise; terminate stubs directly or incorporate them into main transmission lines.

Coupling in PCB Design

- Common impedance coupling occurs when interference sources and devices share conductors.

- Field common-mode coupling induces common-mode voltage due to radiating sources affecting circuit loops.

- Differential Mode Field Coupling involves direct radiation received by wire pairs, mitigated by twisting wires.

Ways to Mitigate Crosstalk in PCB Design

- Proper termination for signal lines sensitive to crosstalk-induced interference.

- Maximize distance between signal lines to reduce capacitive crosstalk.

- Employ ground planes and manage trace spacing, especially at state transition points.

- Introduce ground wires between adjacent signal wires to mitigate capacitive crosstalk.

- Minimize loop area to reduce inductive crosstalk and avoid shared signal loops.

Electromagnetic Interference

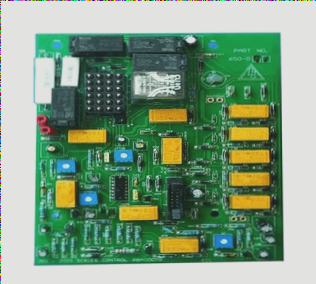

Techniques to Reduce EMI in PCB Design

- Minimize loop area to reduce antenna effect and ensure signals follow a single path.

- Filter power and signal lines with decoupling capacitors, EMI filters, and magnetic components.

- Utilize shielding techniques to minimize electromagnetic interference.

- Lower operating speeds of high-frequency devices.

- Increase PCB board dielectric constant and thickness to contain high-frequency components.

High-Frequency PCB Design Principles

- Ensure stable power supply and ground connections.

- Implement careful wiring and termination to eliminate reflections.

- Minimize capacitive and inductive crosstalk through meticulous wiring and termination.

- Crucially suppress noise to meet EMC requirements.

This revision aims to provide a clearer and more readable overview of techniques to reduce electromagnetic interference (EMI) in PCB design, as well as high-frequency PCB design principles. By implementing these strategies, designers can enhance the performance and reliability of high-speed devices while meeting electromagnetic compatibility (EMC) requirements.