The Importance of Filling Resin in High-Frequency PCB Boards

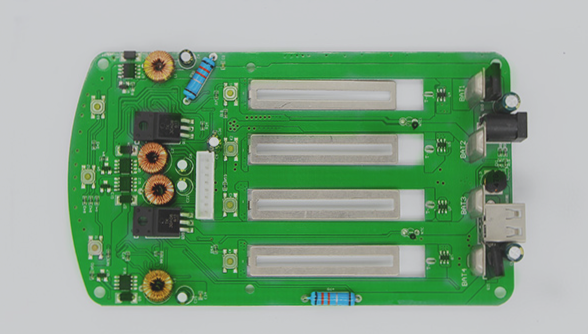

Filling resin material plays a crucial role in determining the performance of high-frequency PCB boards. It serves as a bonding agent that enhances the board’s overall performance.

Key Points:

- Specialized resin is a fundamental raw material in PCB manufacturing.

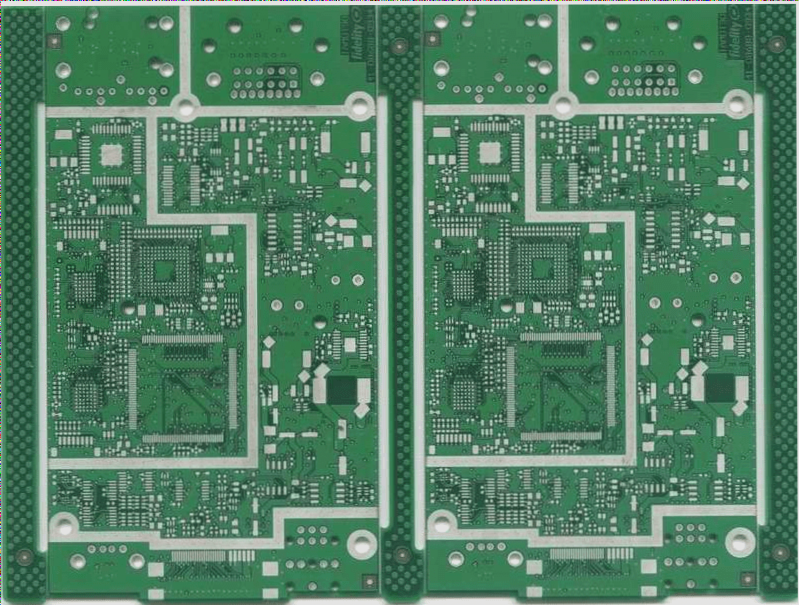

- 5G technology is driving the need for PCBs with multilayer, highly integrated designs.

- Base station PCBs for 5G require improved transmission and heat dissipation capabilities.

Currently, PCB manufacturers prefer using polytetrafluoroethylene (PTFE) as the primary filling resin material. This material, when combined with glass fabric or cermet reinforcements, minimizes cold flow and enhances wear resistance. It also helps in lowering product costs.

Upstream raw materials like electrolytic copper foil for PCBs present high technical and capital barriers, with the majority of global production concentrated in Asia. Leading suppliers of specialized resin materials are primarily overseas, with notable providers from Japan, the U.S., and Taiwan.

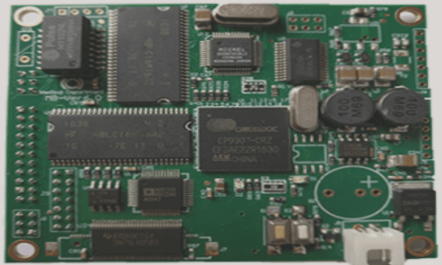

Manufacturers of substrate materials have made significant enhancements to specialized resins to meet the reliability, complexity, and electrical performance requirements of high-frequency and high-speed PCB products. Commonly used PCB materials now include PTFE, epoxy resin (EP), bismaleimide triazine resin (BT), and others, all with low dielectric constant and dielectric loss factors.

While China leads in the application of copper clad laminates and PCBs, there is still a gap in the production of advanced resin materials compared to global standards. To support the growth of 5G technology, China could focus on enhancing production technologies and investing in high-end equipment for future materials.