Component Arrangement Guidelines:

- Under normal conditions, all components should be placed on the same side of the PCB. Exceptions can be made for low-profile devices like chip resistors and capacitors when the top side is densely populated.

- Components should be arranged on a grid, parallel or perpendicular to each other for a neat appearance, avoiding overlap and maintaining compactness.

- High potential difference components should have increased spacing to prevent short circuits.

- Components operating at high voltage should be placed in less accessible areas during debugging.

- Components at the board edge should be at least two board thicknesses away from the edge.

- Components should be evenly distributed with uniform density across the board surface.

Layout Principles Based on Signal Direction:

- Position functional circuit units sequentially following signal flow for efficient layout.

- Facilitate consistent signal flow direction, typically from left to right or top to bottom.

- Place components near input and output terminals for better signal connectivity.

Preventing Electromagnetic Interference:

- Space components emitting strong electromagnetic fields apart and shield sensitive ones.

- Avoid mixing high and low voltage devices and separate strong and weak signal components.

- Minimize magnetic field interference and shield sources effectively with grounding.

Managing Thermal Interference:

- Optimize heat dissipation for heating elements and consider additional cooling solutions if necessary.

- Place high power consumption components for effective heat dissipation and isolation.

- Avoid placing heating components on the bottom layer in two-sided layouts.

Arranging Adjustable Components:

When placing potentiometers, variable capacitors, inductance coils, or micro switches, consider structural requirements and accessibility for adjustments during assembly.

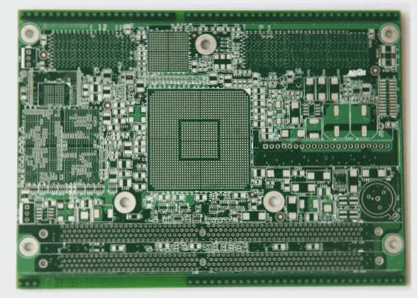

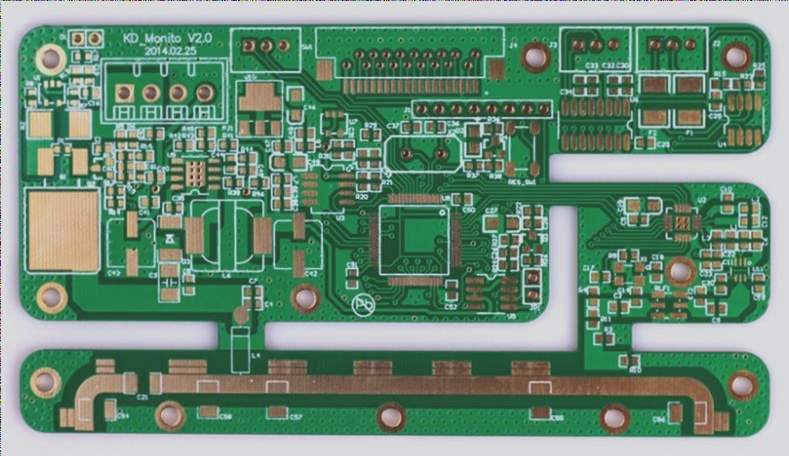

Printed Circuit Board (PCB) Design:

PCBs are vital in electronic product design, connecting components and devices. With advancing technology, PCBs must meet demands for layout, interference resistance, and manufacturability.

Considerations in PCB Design:

- Ensure circuit schematic components match physical objects and network connections.

- Design for power line width, ground wire needs, and impedance matching for high-frequency components.

- Accurately place components for system debugging, ventilation, and heat dissipation.

- Meet manufacturing process requirements for smooth production.