Power Noise Interference in High-Frequency PCB Boards

This article delves into the analysis of power noise interference in high-frequency PCB boards, exploring its various forms and causes. By combining mathematical derivations with practical insights, effective countermeasures are proposed to suppress power noise. Power supply noise stands out as a major source of interference in high-frequency PCBs.

Power Supply Noise Analysis

Power supply noise arises from unwanted signals generated by the power supply or external interference. In high-frequency circuits, power supply noise can disrupt high-frequency signals, emphasizing the need for a low-noise power supply.

Distributed Noise and Impedance

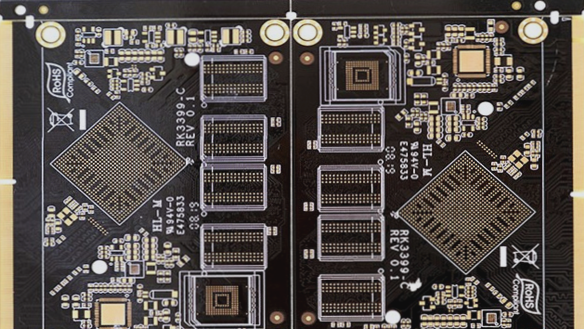

In high-frequency PCBs, a clean ground and power source are crucial. While an ideal power supply would have zero impedance, real-world power supplies possess distributed impedance that introduces noise. To minimize this, utilizing dedicated power supply and ground layers is recommended.

Power Supply in High-Frequency Circuit Design

Implementing the power supply as a layer design in high-frequency circuits outperforms a bus design. This design ensures the circuit follows the path of least impedance, with the power plane acting as a signal loop to minimize signal loops and reduce noise.

Common Mode Field Interference

Common mode field interference occurs between the power supply and ground due to common mode voltage interference. This interference is influenced by the relative strengths of electric and magnetic fields, impacting the receiving section through induced common-mode voltage in the series loop.

Inter-line Interference

Inter-line interference arises from mutual capacitance and inductance between parallel circuits, introducing interference due to voltage and current in the source circuit. Capacitive and inductive coupling play a role in common and differential mode noise.

Power Line Coupling

Power line coupling involves electromagnetic interference affecting AC or DC power cables, which can indirectly impact high-frequency circuits. This form of power supply noise transmission is essential to address in PCB design.

Strategies to Eliminate Power Supply Noise Interference

-

Minimize Through-Hole Impact

Be cautious with through-holes on the PCB as they can increase loop area and potential for noise if not properly managed.

-

Ensure Adequate Grounding for Cables

Each signal line should have its own dedicated signal loop to minimize interference.

-

Install Power Supply Noise Filters

Use bidirectional RF filters to block both internal and external noise, enhancing system immunity.

-

Use Power Isolation Transformers

Isolate common-mode ground loops to minimize interference between power circuits and signal cables.

-

Implement Power Regulators

Employ power regulators to reduce power supply noise and improve system performance.

-

Optimize PCB Layout

Avoid routing power supply lines along the PCB edge to prevent interference with other circuits.

-

Separate Analog and Digital Power Supplies

Separate analog and digital power supplies to minimize digital noise interference.

-

Avoid Overlapping Power Supplies Across Different Layers

Stagger power supplies between layers to reduce noise coupling through parasitic capacitance.

-

Isolate Sensitive PCB Components

Ensure sensitive components are isolated to protect them from external interference.