(1) High frequency circuits typically have high integration and high line density. The use of multi-layer boards is not only necessary for wiring, but also an effective means of reducing interference. Protel for Windows V1.5 can provide 16 copper wire layers and 4 power supply layers. Reasonable selection of layers can greatly reduce the size of printed circuit boards, fully utilize shielding in the middle layer, better achieve nearby grounding, effectively reduce parasitic inductance, shorten the transmission length of signals, and greatly reduce cross interference between signals. According to some data, when using the same material, the noise of a four layer board is 20dB lower than that of a double-sided board. However, the more layers there are, the more complex the manufacturing process becomes and the higher the cost.

(2) Try to minimize the bending of leads between pins in high-speed circuit devices. The lead wire for high-frequency circuit wiring should be fully straight, and if necessary, a 45 degree bend or arc can be used. This requirement is only used to improve the fixed strength of steel foil in low-frequency circuits, while meeting this requirement in high-frequency circuits can reduce the external transmission and mutual coupling of high-frequency signals. When using Protel for wiring, two settings can be made in advance: first, set the 45/90 Line or 90 ArcLine mode in the Track Mode submenu of the OpTIons menu for wiring reservation; Another option is to select Add Arcs in the RoutTingPasses dialog box opened by selecting the Setup Autorouter option in the Auto menu, so that the corners can be curved at the end of the automatic routing.

(3) The shorter the lead between the pins of high-frequency circuit components, the better. The most effective way for Protel to achieve the shortest path is to reserve wiring for some critical high-speed networks before automatic routing. Firstly, open Edit Net in the Netlstmenu, and a Change Net dialog box submenu will appear. Select the optimization mode of OpTimizeMethod as Shortest in this dialog box. Secondly, when considering the overall layout of components, use the Placement Tools Show and Density in the Auto menu to compare and adjust, compact the components, and coordinate with the Length selection function in the Netlist menu and Info menu to measure the wiring length of the critical network that needs to be minimized.

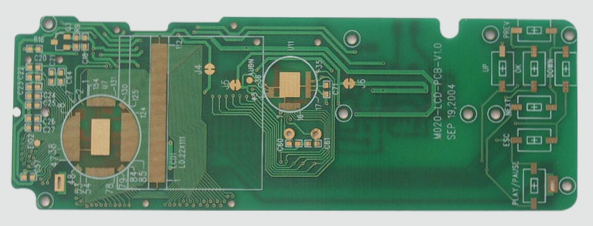

(4) Try to minimize interlayer jumping of leads between pins in high-frequency circuit devices. The so-called fewer interlayer jumps in the lead wire, the better, which means that as little as possible via is used in the component connection process. According to measurements, a via may bring about a distributed capacitance of approximately 0.5 pF. Reducing the number of VIAs can significantly improve speed. Protel software specifically provides this feature. There is an Advanced column in the RoutingPasses dialog box opened by the Setup Autorouter option in the Auto menu. Set Smoothing to On in the Advanced column< Img src=“ https://www.wellcircuits.com/wp-content/uploads/20230110/424bf91a-b41e-11ee-9a98-705ab6a7e753/f82e7feda79ba4f92de55d386808d960.jpg

(5) For high frequency circuits wiring, attention must be paid to the cross interference caused by the parallel wiring of signal lines in a short distance If parallel distribution cannot be avoided, a large area can be arranged on the potential side of the parallel signal lines to significantly reduce interference Parallel routing in the same layer is also unavailable, but the direction of routing in two adjacent layers must be perpendicular to each other This is not complicated to do in Protel, but it is easy to ignore In the Routing Layers dialog box opened by the Setup Autorouter item in the Auto menu, it is allowed to pre-set the routing direction of each layer There are three types of horizontal, vertical, and no preference directions for selection Many users are using to choose no preference without specific orientation, thinking that this is a high routing rate

However, in high-frequency circuits wiring, it is better to take horizontal and vertical wiring alternately in adjacent layers. Parallel wiring in the same layer cannot be avoided, but ground wires can be laid in large areas on the reverse side of the printed board to reduce interference. This is for commonly used double-sided boards. The multilayer board can use the middle power layer to achieve this function. Protel software used to only provide a simple Fill function to meet this demand. Now Protel under Windows also provides a more powerful function to place Polygon Plane in the Place option of the Edit menu, that is, polygonal grid strip copper foil surface. If the polygon is used as a surface of the entire printed board when it is placed, and the grid bar is connected to the GND network of the circuit, this function will be able to realize the copper laying operation on one side of the entire printed board. In addition to improving the high-frequency circuit wiring ability just mentioned, the high-frequency circuit wiring after copper coating is also very beneficial to heat dissipation, printed board strength, etc.

Additionally, if a tinned grid bar is added to the fixed position on the metal chassis of the circuit board, it can not only improve the fixed strength and ensure good contact, but also make use of the metal chassis to form a suitable public line. After opening this function in the software menu, you can see a Place Polygon Plane dialog box, which will ask whether you want to connect the placed polygon grid bar with the network. If you connect this item, when you exit the dialog box, you will be prompted to give the name of the network you want to connect. If you connect the GND network, high-frequency circuits will play the role of a shielding layer. At the same time, you will be asked whether the pattern of laying copper is the horizontal bar, vertical bar, or both grids. The grid will have a better shielding effect and the size of the grid is used as the purpose to determine according to the interference frequency of the key shielding.