1. The lithium-ion batteries used in PCB factories are highly sensitive to temperature variations.

2. If the temperature drops too low, the lithium-ion battery will cease to function effectively.

3. Conversely, if the temperature rises excessively, we can recall the unfortunate incident involving Samsung.

4. The charging and discharging processes of lithium-ion batteries involve chemical reactions.

5. Beneath a seemingly calm exterior, lithium ions travel back and forth between the anode and cathode.

6. When a lithium-ion battery charges, the lithium atom at the positive electrode loses electrons and is oxidized into lithium ions.

7. These lithium ions then migrate to the negative electrode through the electrolyte, where they gain an electron and are reduced back to lithium atoms.

8. During discharge, this process is reversed.

9. Additionally, to prevent the positive and negative electrodes from coming into direct contact and causing a short circuit, a separator with fine pores is utilized to keep them apart.

1. Issues such as lithium battery swelling, high temperatures, and explosions are typically linked to overcharging, over-discharging, and excessive current, all of which can damage the battery. These problems are quite common, while ultra-low temperature conditions are rare. In contrast, the challenge of managing ultra-high temperatures is becoming increasingly prevalent due to the rising power demands of electrical devices. Therefore, achieving a stable current and effective heat dissipation is crucial. This brings us to the significance of ceramic circuit boards.

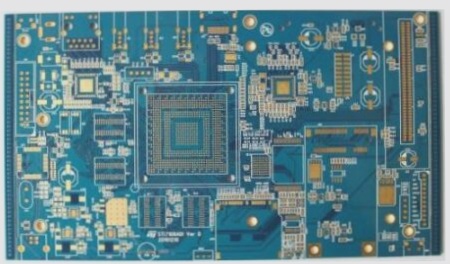

2. In PCB design, ceramic circuit boards currently offer the highest thermal conductivity available in the market. It is widely understood that high thermal conductivity allows ceramic circuit boards to effectively dissipate the heat generated by lithium-ion batteries. How do we address the issue of high current? In addition to the circuit control system, the quality of the circuit board plays a significant role. A circuit board with higher precision ensures a more uniform circuit, resulting in a more stable current flow.

3. Huawei has pioneered the development of graphene lithium-ion batteries, where graphene primarily serves as a heat conductor. However, the commercialization of graphene is still in progress, and it has a considerable journey ahead. The key concern is when this technology will become commercially viable, as only commercialized technologies can deliver benefits to users and drive the lithium battery industry forward. Ceramic circuit boards, being a mature product, remain at the forefront for now.

4. Ceramic circuit boards continue to hold their ground in this market. Technological advancements do not threaten their status but instead provide them with ongoing opportunities for enhancement. The potential for ceramic circuit boards is vast, with nearly limitless possibilities for iterative improvements. Our focus should be on maximizing their utility.

5. Whether the future favors ceramic circuit boards or graphene is beyond our immediate consideration. What matters is identifying which technology can best meet current demands. The market ultimately determines the fate of a product. Ceramic circuit boards extend beyond just lithium-ion batteries; they also have promising applications in industries like LED technology and aerospace. It is likely that ceramic circuit boards will leave a significant mark on the history of the electronics industry in the years to come.