The thermal conductivity of a copper-based PCB is a crucial parameter for assessing its heat dissipation performance. It indicates how effectively the copper substrate conducts heat from the circuit level through the thermal insulation layer. The thermal conductivity typically ranges between 2 W/m·K and 398 W/m·K.

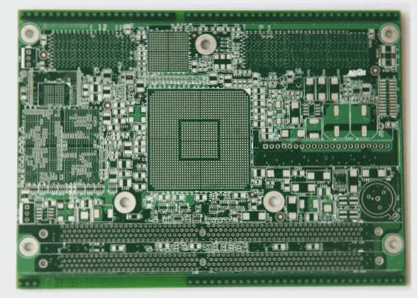

Characteristics of copper base PCB

1. The thermal conductivity of copper-based PCB surpasses that of aluminum and iron substrates, making it ideal for applications in high-frequency circuits, environments with significant temperature fluctuations, and precision communication equipment. Copper-based PCBs offer advantages such as superior thermal conductivity, electrical insulation, and mechanical processing capabilities. The substrate material typically consists of copper plates, ensuring excellent thermal conductivity and vastly superior heat dissipation compared to aluminum and iron.

2. Thermal Insulation Layer

The thermal insulation layer is a critical component of copper base PCBs, with copper foil thickness typically ranging from 35um to 280um to support high current capacity. In contrast to aluminum substrates, which exhibit high thermal resistance and insufficient heat dissipation during operation, the use of copper-based PCBs is recommended to achieve optimal heat dissipation and ensure product stability.

3. Heat Dissipation in High-Power Density Environments

Copper base PCBs are commonly chosen as heat dissipation substrates in products with high power density. Some substrates may struggle with aging, mechanical stress, and thermal resistance, whereas copper base PCBs excel in effective heat dissipation.

High-Temperature Resistance and Soldering

The high-temperature resistance of copper base PCBs reaches approximately 300-400 degrees Celsius, contingent on factors such as solder paste quality and lamp bead specifications. Welding typically lasts 30-50 seconds without damaging components, with actual tin melting occurring within just 10 seconds, primarily due to preheating and heat dissipation considerations.

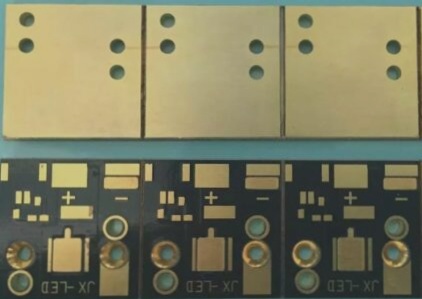

Distinguishing Copper Substrates from Ceramic Substrates

1. Material Properties

Copper base PCBs predominantly feature copper, renowned for its exceptional thermal and electrical conductivity. This property enables efficient heat dissipation, making it well-suited for high-power electronic devices. Conversely, ceramic substrates leverage ceramic materials for superior insulation and high-temperature resilience, preventing current leakage and supporting stable operation in high-frequency electronic environments.

2. Manufacturing Processes

Manufacturing copper base PCBs involves straightforward processes like cutting, cleaning, etching, and copper foil drilling. Chemical etching patterns copper foils to form structures such as wires and solder pads. In contrast, ceramic substrate production entails more intricate steps, including preparation, molding, and high-temperature sintering of ceramic materials to ensure dense, high-quality insulation.

3. Application Domains

Due to its excellent conductivity and thermal properties, copper-based PCBs find extensive use in heat dissipation and current transmission for power electronics, automotive electronics, and LED lighting. Ceramic substrates, favored for their insulation and high-temperature resilience, excel in signal transmission for RF power amplifiers and applications in communication, satellite technology, and radio frequency equipment.

In summary, copper base PCBs leverage copper foil as a conductive layer supported by a substrate, making them ideal for high-precision and high-frequency circuit applications. Their stable signal transmission performance enhances their suitability for high-frequency circuits.