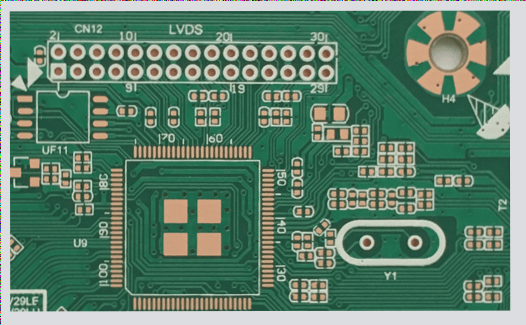

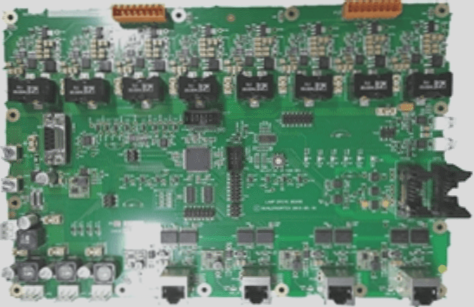

As PCB products become increasingly complex, with higher performance requirements, the density of printed circuit boards and the frequency of related components continue to rise. Engineers are encountering more challenges in high-density PCB design.

In addition to the well-known signal integrity (SI) issues, the next major focus in high-speed PCB technology is expected to be power integrity (PI), EMC/EMI, and thermal analysis.

Furthermore, with the intensifying competition, PCB manufacturers are under pressure to meet product delivery deadlines. Effectively using advanced EDA tools, optimization techniques, and processes to complete designs with both high quality and efficiency has become a critical challenge for both system manufacturers and design engineers.

Hot Spot: Transitioning from Signal Integrity to Power Integrity

In high-speed design, the primary concern is typically signal integrity. Signal integrity refers to the quality of the signal transmitted along the signal path. When a signal reaches the receiving chip’s pins with the required timing, duration, and voltage amplitude, the circuit is considered to have good signal integrity. Signal integrity issues arise when the signal fails to behave as expected or when the signal quality is insufficient for the system to operate stably over time.

Signal integrity primarily manifests in issues like delay, reflection, crosstalk, timing, and oscillation, among others. It is commonly believed that signal integrity problems begin to arise when the system operates at 50MHz, and as the system frequency and equipment speed increase, these problems become more pronounced.

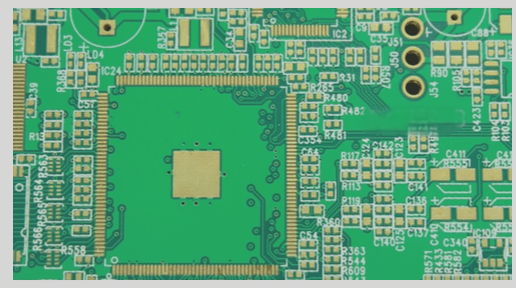

Parameters of components and the PCB board, the layout of components on the PCB, high-speed signal routing, and other factors can lead to signal integrity issues, causing system instability or even failure to function properly. Over decades of development in signal integrity technology, both the theoretical framework and analysis methods have matured. Signal integrity challenges are not just a concern for individual engineers; they involve multiple stages in the design chain, encompassing system designers, hardware engineers, PCB designers, and even the manufacturing process.

To address signal integrity issues, advanced simulation tools are essential. Power Integrity, a relatively newer field in comparison to signal integrity, is now considered one of the most significant challenges in modern high-speed, high-density PCB design. Power integrity refers to the varying impedance characteristics of the power distribution system (PDS) at different frequencies in high-speed systems. This results in voltage fluctuations between the circuit board and the layers on the PCB, causing power discontinuities, noise, and potential failure in chip functionality. Moreover, high-frequency radiation exacerbates these issues, leading to potential EMC/EMI problems.

Power integrity issues can only be addressed by optimizing layer spacing, PCB layout, and other techniques aimed at reducing power and ground noise (e.g., proper matching to minimize reflection problems), while also mitigating EMC/EMI effects. In relation to signal and power integrity, “signal integrity is a concept in the time domain, while power integrity is best understood as a concept in the frequency domain. The challenges in power integrity are even more complex than those of signal integrity.” Power integrity demands advanced skills from engineers and represents a new challenge in high-speed design. It spans beyond the board level, also encompassing chip and package design. Engineers involved in high-speed circuit board design should ensure power integrity is addressed alongside signal integrity.

“Softening” your design through simulation: Simulation serves as a virtual prototype test, encompassing all aspects of the problem.

As PCB designs grow increasingly complex, engineers cannot implement every solution directly, making advanced simulations indispensable in lieu of physical experiments. In today’s system design, engineers face not only challenges posed by high-speed, high-density circuit boards but also the pressure of rapid product introductions, making simulation a vital tool for system design.

In addition to the well-known signal integrity (SI) issues, the next major focus in high-speed PCB technology is expected to be power integrity (PI), EMC/EMI, and thermal analysis.

Furthermore, with the intensifying competition, PCB manufacturers are under pressure to meet product delivery deadlines. Effectively using advanced EDA tools, optimization techniques, and processes to complete designs with both high quality and efficiency has become a critical challenge for both system manufacturers and design engineers.

Hot Spot: Transitioning from Signal Integrity to Power Integrity

In high-speed design, the primary concern is typically signal integrity. Signal integrity refers to the quality of the signal transmitted along the signal path. When a signal reaches the receiving chip’s pins with the required timing, duration, and voltage amplitude, the circuit is considered to have good signal integrity. Signal integrity issues arise when the signal fails to behave as expected or when the signal quality is insufficient for the system to operate stably over time.

Signal integrity primarily manifests in issues like delay, reflection, crosstalk, timing, and oscillation, among others. It is commonly believed that signal integrity problems begin to arise when the system operates at 50MHz, and as the system frequency and equipment speed increase, these problems become more pronounced.

Parameters of components and the PCB board, the layout of components on the PCB, high-speed signal routing, and other factors can lead to signal integrity issues, causing system instability or even failure to function properly. Over decades of development in signal integrity technology, both the theoretical framework and analysis methods have matured. Signal integrity challenges are not just a concern for individual engineers; they involve multiple stages in the design chain, encompassing system designers, hardware engineers, PCB designers, and even the manufacturing process.

To address signal integrity issues, advanced simulation tools are essential. Power Integrity, a relatively newer field in comparison to signal integrity, is now considered one of the most significant challenges in modern high-speed, high-density PCB design. Power integrity refers to the varying impedance characteristics of the power distribution system (PDS) at different frequencies in high-speed systems. This results in voltage fluctuations between the circuit board and the layers on the PCB, causing power discontinuities, noise, and potential failure in chip functionality. Moreover, high-frequency radiation exacerbates these issues, leading to potential EMC/EMI problems.

Power integrity issues can only be addressed by optimizing layer spacing, PCB layout, and other techniques aimed at reducing power and ground noise (e.g., proper matching to minimize reflection problems), while also mitigating EMC/EMI effects. In relation to signal and power integrity, “signal integrity is a concept in the time domain, while power integrity is best understood as a concept in the frequency domain. The challenges in power integrity are even more complex than those of signal integrity.” Power integrity demands advanced skills from engineers and represents a new challenge in high-speed design. It spans beyond the board level, also encompassing chip and package design. Engineers involved in high-speed circuit board design should ensure power integrity is addressed alongside signal integrity.

“Softening” your design through simulation: Simulation serves as a virtual prototype test, encompassing all aspects of the problem.

As PCB designs grow increasingly complex, engineers cannot implement every solution directly, making advanced simulations indispensable in lieu of physical experiments. In today’s system design, engineers face not only challenges posed by high-speed, high-density circuit boards but also the pressure of rapid product introductions, making simulation a vital tool for system design.