High-Frequency PCB Design Tips for Optimal Interconnections

- Ensure transmission line corners are at a 45° angle to reduce return loss.

- Use high-performance insulated circuit boards with precise insulation constant values to manage electromagnetic fields effectively.

- Enhance PCB design specifications for high-precision etching to address issues related to microwave frequency.

- Avoid components with protruding leads in high-frequency environments; opt for surface mount components instead.

- Avoid via processing on signal vias in sensitive boards to prevent lead inductance.

- Choose electroless nickel plating or immersion gold plating processes for better skin effect at high frequencies.

- Consider using a solder dam instead of covering the entire board surface with solder mask material to maintain electromagnetic energy balance.

Implementing these techniques in high-frequency PCB design can optimize your interconnection layout. Remember, a back-side copper-clad coplanar microstrip design may offer a more cost-effective solution compared to a stripline design.

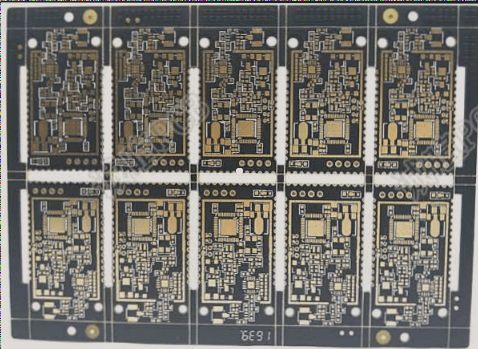

About WellCircuits Limited

WellCircuits Limited specializes in manufacturing high-precision double-sided, multilayer, and impedance-controlled circuit boards. Our product range includes boards with blind buried vias, thick copper, HDI, backplanes, and rigid-flex combinations, catering to diverse customer requirements such as buried capacitance and resistance, Golden Finger, and more.