In 3D printing, we typically avoid using solid infill, meaning the density of the infill significantly affects the printed part’s properties. Using less infill material reduces both the time and cost of printing, as well as the overall strength of the part. The infill density is referred to as the infill percentage.

Therefore, when printing, it’s important to select the appropriate infill percentage based on the project’s requirements:

0%-20% is ideal for parts that are intended for display only and do not need load-bearing capabilities. However, if the part has a large flat surface on top, increasing the infill density may be necessary to provide internal support.

20%-40% is suitable for parts that require some load-bearing ability. This range offers nearly the same strength as solid parts, but at a reduced cost.

40%-100% is appropriate for parts that need high load-bearing strength. However, the strength gain diminishes when the infill percentage exceeds 60%.

The strength of a part is directly related to its infill percentage. For example, if the infill is 25%, increasing it to 50% typically boosts the part’s strength by about 25%. When the percentage increases from 50% to 75%, the strength improvement is usually only around 10%.

In addition to infill density, factors such as shell thickness and the part’s orientation during printing also play crucial roles in determining its strength. If you have specific requirements, feel free to contact Wellcircuits, and we will do our best to provide you with satisfactory service.

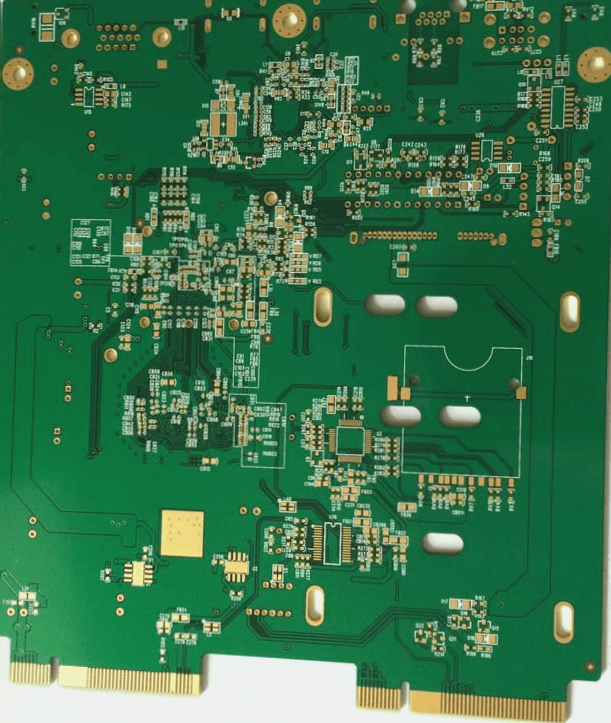

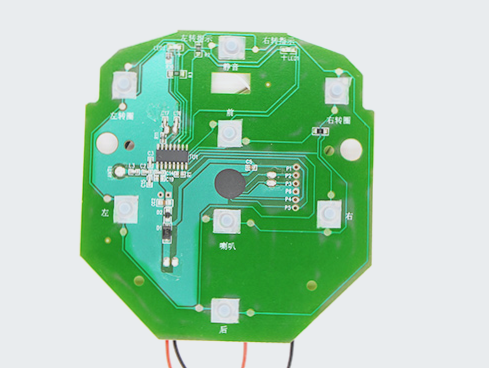

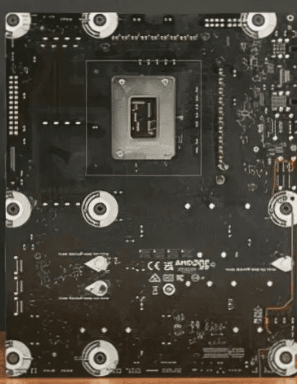

If you have any questions regarding PCBs or PCBA, please reach out to me at info@wellcircuits.com.