Hi all,

We’re doing a small rubber bezel to “close off” our extruded aluminium enclosure from dust as much as possible.

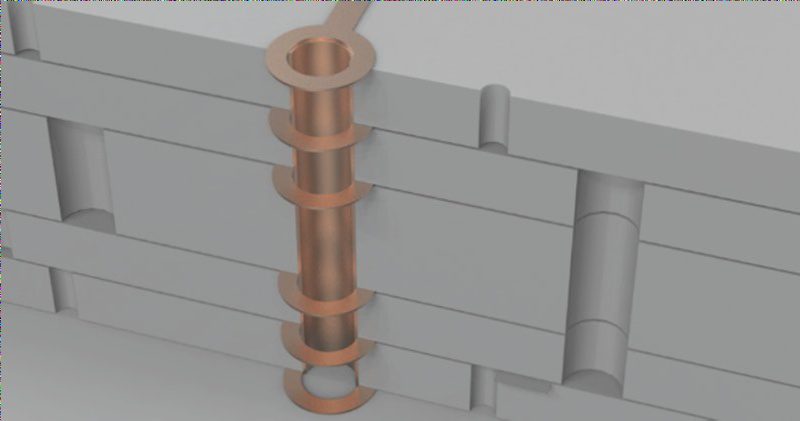

One of the challenges we have here is that we have an SD Card slot hole in one of our end plates. To cover this, we aim to create a small “extension” of the rubber bezel that goes up and covers this SD card slot. I’ve tried to add a cross-section to show what this would look like from the side – the black part is the rubber, while the grey is the enclosure end plate.

However, to make sure this extension doesn’t get loose, we also want to add a small strip/hole in the enclosure end plate where we can “press” a small part of the rubber bezel into – to make it stick. The rubber has a hardness similar to car tires.

Our question is if any of you have any guidance on what kind of design works optimally for ensuring this sticks – and doesn’t get too resistant to pressure into the hole?

Also, we’re not familiar with how much complexity a typical rubber mold can handle – any experience on this?

Thanks a lot,