What are the interconnection methods for PCB boards?

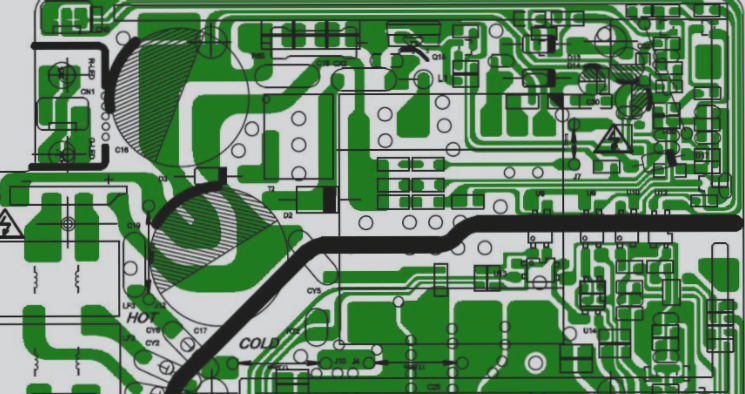

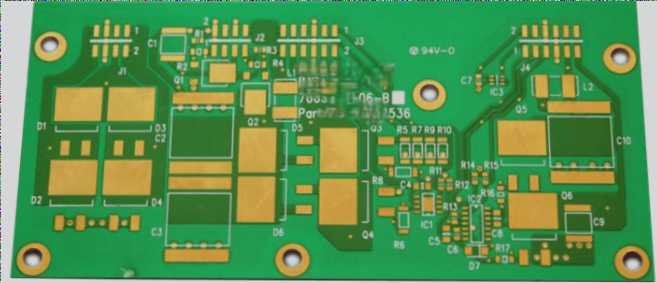

Electronic components and electromechanical devices feature electrical contacts, and the connection between two discrete contacts is referred to as interconnection. To achieve the intended functionality, electronic devices must be interconnected according to the schematic circuit diagram. So, what methods are available for interconnecting PCB boards? Here’s a brief summary of the two primary approaches:

1. Soldering Method

The advantages of this connection technique include simplicity, low cost, and high reliability, helping to prevent failures caused by poor contact. However, the downside is that interchangeability and maintenance can be somewhat inconvenient. This method is generally suitable for components with fewer external leads.

What are the interconnection methods for PCB boards?

1. PCB Wire Soldering

This method eliminates the need for connectors, as the external connection points on the PCB can be directly soldered to components or other external parts using wires. For instance, this applies to the horn and battery box in a radio.

What are the interconnection methods of PCB boards?

2. PCB Cable Soldering

Two PCB printed boards can be linked via a flat cable, providing a reliable connection that minimizes the risk of errors. Additionally, the relative positioning of the two boards is not restricted.

What are the interconnection methods of PCB boards?

3. Direct Soldering Between PCBs

The printed boards are soldered directly together. This approach is commonly employed for connecting two boards at a 90-degree angle, resulting in a unified PCB component.

What are the interconnection methods of PCB boards?

4. Connector Connection Method

In more complex instruments and equipment, connector connections are frequently utilized. This modular structure not only ensures high-quality mass production but also reduces system costs while facilitating easier debugging and maintenance. When equipment malfunctions, maintenance personnel can quickly identify which board is faulty without needing to diagnose individual components, which can be time-consuming. They can simply replace the suspected board to expedite troubleshooting, minimize downtime, and enhance equipment utilization. The replaced circuit board can be repaired later and kept as a spare part.

What are the interconnection methods of PCB boards?

1. Printed Board Socket

In more intricate instruments and equipment, this type of connection is often used. A printed plug is created from the edge of the PCB, designed to match the size of the socket, the number of contacts, the spacing of the contacts, and the positioning hole, ensuring compatibility with specialized PCB sockets.

What are the interconnection methods of PCB boards?

2. Standard Pin Connection

This method is suitable for external connections of printed boards, particularly in smaller instruments. When two printed boards are connected via standard pins, they are typically aligned either parallel or perpendicular, facilitating mass production.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me

Electronic components and electromechanical devices feature electrical contacts, and the connection between two discrete contacts is referred to as interconnection. To achieve the intended functionality, electronic devices must be interconnected according to the schematic circuit diagram. So, what methods are available for interconnecting PCB boards? Here’s a brief summary of the two primary approaches:

1. Soldering Method

The advantages of this connection technique include simplicity, low cost, and high reliability, helping to prevent failures caused by poor contact. However, the downside is that interchangeability and maintenance can be somewhat inconvenient. This method is generally suitable for components with fewer external leads.

What are the interconnection methods for PCB boards?

1. PCB Wire Soldering

This method eliminates the need for connectors, as the external connection points on the PCB can be directly soldered to components or other external parts using wires. For instance, this applies to the horn and battery box in a radio.

What are the interconnection methods of PCB boards?

2. PCB Cable Soldering

Two PCB printed boards can be linked via a flat cable, providing a reliable connection that minimizes the risk of errors. Additionally, the relative positioning of the two boards is not restricted.

What are the interconnection methods of PCB boards?

3. Direct Soldering Between PCBs

The printed boards are soldered directly together. This approach is commonly employed for connecting two boards at a 90-degree angle, resulting in a unified PCB component.

What are the interconnection methods of PCB boards?

4. Connector Connection Method

In more complex instruments and equipment, connector connections are frequently utilized. This modular structure not only ensures high-quality mass production but also reduces system costs while facilitating easier debugging and maintenance. When equipment malfunctions, maintenance personnel can quickly identify which board is faulty without needing to diagnose individual components, which can be time-consuming. They can simply replace the suspected board to expedite troubleshooting, minimize downtime, and enhance equipment utilization. The replaced circuit board can be repaired later and kept as a spare part.

What are the interconnection methods of PCB boards?

1. Printed Board Socket

In more intricate instruments and equipment, this type of connection is often used. A printed plug is created from the edge of the PCB, designed to match the size of the socket, the number of contacts, the spacing of the contacts, and the positioning hole, ensuring compatibility with specialized PCB sockets.

What are the interconnection methods of PCB boards?

2. Standard Pin Connection

This method is suitable for external connections of printed boards, particularly in smaller instruments. When two printed boards are connected via standard pins, they are typically aligned either parallel or perpendicular, facilitating mass production.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me