The Evolution of Circuit Boards and Laser Cutting Technology

Introduction

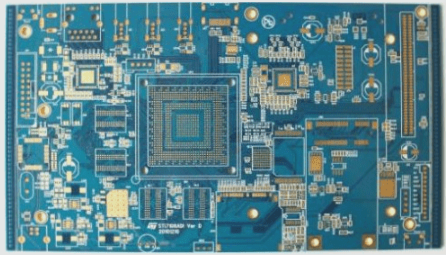

The demand for portable products has led to advancements in circuit board technology, evolving from single-sided to double-sided, multi-layer, flexible, and rigid-flex designs. These designs aim for higher precision, density, and reliability.

Flexible Circuit Board (FPC) Production

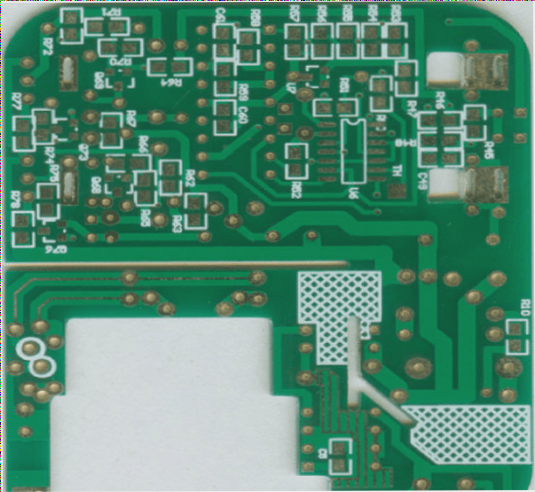

The base material of FPC boards is copper, covered with a protective polyimide film. Laser cutting technology is crucial for creating precise connections between FPC boards and electronic devices.

Laser Cutting Techniques

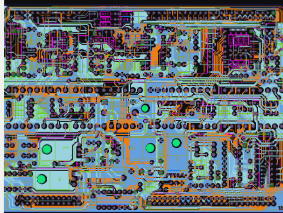

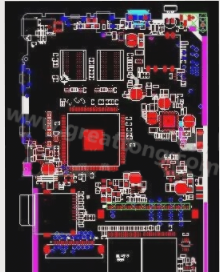

Batch processing of FPC shapes is commonly done through punching, while laser cutting is preferred for small batches and samples. Manufacturers have developed UV laser cutting machines for creating FPC samples, utilizing cutting techniques like cursor point recognition and character recognition.

Plug Edge Recognition

Enhancing laser cutting precision for FPC boards involves plug edge recognition methods. By utilizing a CCD-based approach, manufacturers can compensate for expansion and contraction deformations, ensuring accurate cutting of FPC board plugs.

Expansion and Contraction Principles

The expansion and contraction of FPC boards during production can lead to shape processing inaccuracies. Employing contour laser cutting technology and CCD reference point recognition corrects distortion, improving the processing accuracy of FPC board plugs.

Experimental Testing

- Materials and Equipment: Ten FPC boards, ASIDA JG13 UV laser cutting machine, and a 2D image projector.

- Methods and Data: Laser equipment accuracy is tested, and circuit boards with different expansion/contraction rates are cut to measure cutting precision.

- Equipment Accuracy Testing: The operational state and cutting accuracy of the equipment are assessed by measuring deviations from theoretical values after cutting the circuit board multiple times.

Cutting Accuracy of Different Expansion and Contraction Templates

When producing PCBs, factors like splicing, electroplating, lamination, and temperature changes can lead to models shrinking and deforming. Laser equipment can compensate for FPC board expansion and contraction, but excessive deformation may affect cutting shape accuracy within customer specifications.

Assessing Cutting Accuracy

Seven types of circuit board materials with expansion and contraction rates ranging from 0.1‰ to 3.0‰ were tested to evaluate cutting accuracy. Results showed that when the shrinkage rate is below 0.8‰, cutting accuracy stays within ±0.05mm. However, as the rate increases, both average cutting deviation and variance values rise, impacting accuracy.

FPC Board Cutting Technology

For shrinkage rates exceeding 0.8‰, average cutting deviation and variance exceed acceptable limits, posing challenges for laser cutting. By using a laser cutting machine with a resolution of ±3μm and a positioning system based on the plug edge, distortion corrections can be made to ensure cutting accuracy, even with significant expansion and contraction rates.

Addressing Cutting Deviations

When FPC board expansion and shrinkage rates surpass 0.8‰, maintaining cutting accuracy within ±0.05mm tolerance becomes difficult. To overcome this challenge, a new CCD system is utilized to establish a fresh positioning reference point for plugs, compensating for distortion and ensuring the shape accuracy of the final board.