Automation in PCBA Production Lines

When it comes to automating PCBA electronic assembly production lines, a common question arises: which task is simpler, assembly or testing? While robotic arms can assist in assembly movements, the automation of testing processes is also being explored.

Challenges in Implementation

However, a significant challenge in implementing automation is the shortage of skilled individuals capable of adapting the equipment for use. Whether it’s utilizing robotic arms for assembly or testing, or employing modular methods, the tolerance and adaptability of equipment and fixtures play a crucial role in ensuring efficient production and preventing errors.

Considerations for Automation

One major concern during automation implementation is avoiding “automation for the sake of automation.” It is essential to consider the return on investment (ROI) when deciding between automation and maintaining manual processes. Shenzhen Grace Express recommends evaluating the economic benefits and costs to make informed decisions.

Automated Testing of Mobile Phones

For example, in the production of mobile phones, automated testing post-PCBA assembly involves leveraging robotic arms to replace manual tasks. The self-test program runs on the phone, communicating wirelessly for commands, with the final cosmetic inspection delegated to an image recognition system.

Automated Circuit Board Testing

Automated testing at the circuit board level includes AOI, ICT/MDA, and FVT tests. AOI and ICT/MDA tests are already automated, with efforts focused on improving loading and unloading processes. Robotic arms can assist in FVT testing by automating loading and unloading tasks.

Automatic Assembly of PCBs

PCB assembly is highly automated, especially with pure SMT production. For through-hole components, the PIP/PIH process is recommended, or robotic arms can be used for automatic soldering. Transitioning SMD parts to through-hole solder paste and employing paste-in-hole processes for through-hole components are also common practices.

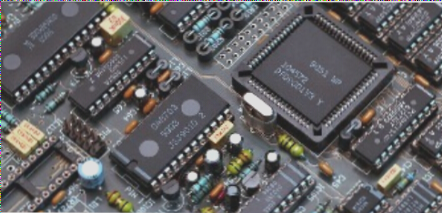

Complete Machine Assembly

Current automation efforts in assembly focus on the “screw lock” segment, with manufacturers exploring systems that can automatically feed screws. Some use robotic arms alongside traditional tools for efficient assembly processes.

The Key Challenge in PCBA Machine Assembly: Flexible Cable Assembly

One of the most demanding aspects of PCBA machine assembly lies in the handling of flexible cables (FPC). These cables are intricate and fragile, making it challenging to control their orientation during assembly. Despite the efforts invested, the returns may not always align with the level of investment.

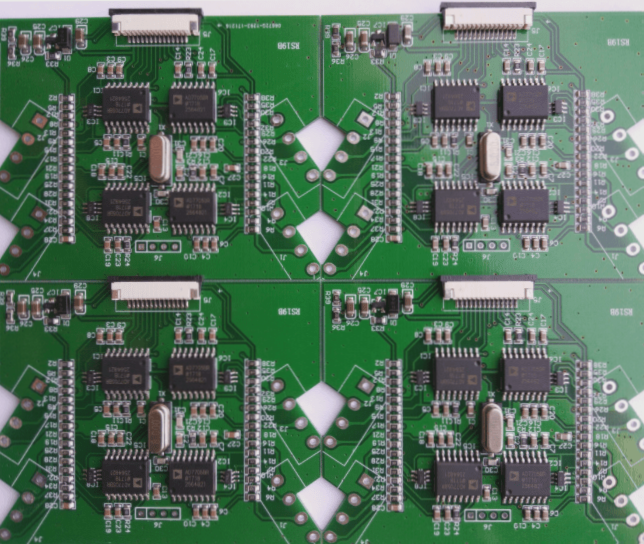

Enhancing Automation Processes for Efficient PCB Manufacturing

Efficient PCB manufacturing requires seamless coordination between incoming materials and automation processes. Adapting packaging for automated loading and unloading is crucial to eliminate manual intervention in component arrangement. While this adjustment may lead to higher packaging costs, it is essential for maximizing the benefits of assembly automation.