Advantages of Green PCB Boards in Electronics Industry

1. Why Green is the Most Common Color for PCB Boards?

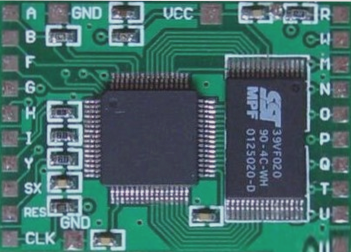

- Green solder mask is preferred for its maturity, simplicity, and environmental friendliness.

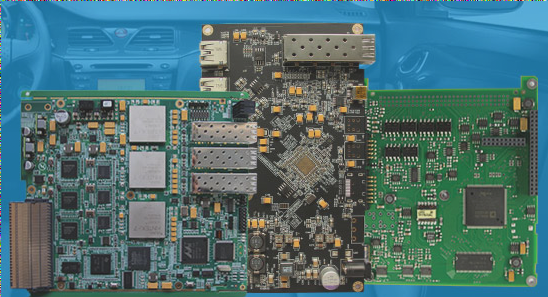

- Other PCB board colors include white, yellow, red, blue, and even unique hues like chrysanthemum and purple.

- Different colors serve to differentiate product samples and stages of development.

2. Benefits of Green Solder Mask in PCB Processing

- Green ink has a long history, is cost-effective, and offers numerous advantages.

- Green PCB boards are more favorable in yellow light rooms during production.

- Green bottom plates are advantageous for optical positioning calibration during SMT patch processing.

3. Environmental Considerations and Practicality

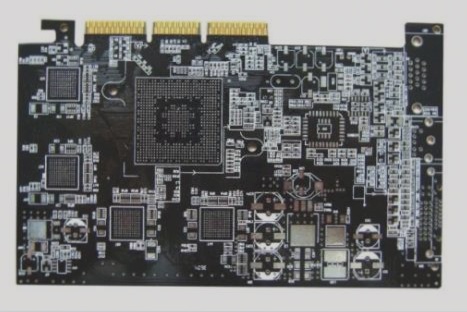

- Green PCBs are environmentally friendly and do not release toxic gases when recycled at high temperatures.

- Other colors like blue and black may have weak electrical conductivity and pose short circuit risks.

- Darker colors like black, purple, and blue can complicate inspection and maintenance processes.

While the color of PCB boards does not impact performance, green PCBs are preferred for their visibility, ease of recognition, and environmental friendliness in the electronics industry.