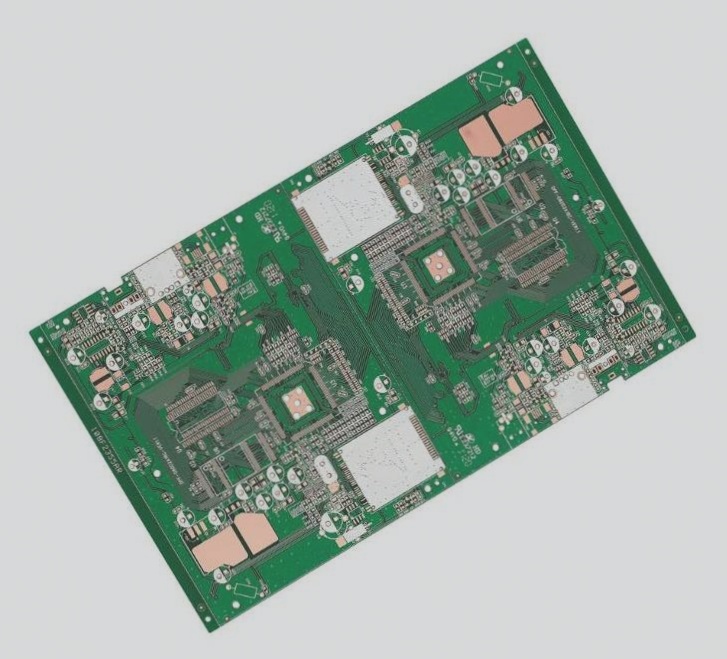

Hey, i want to mount one pcb onto another at 90degrees using a typical 2.54 pitch right angle header.

The issue is that the holes need to be quite close to the edge on one of the boards and i’m not sure if they are too close to get manufactured.

Is there a rule of thumb or formula for how close a hole can be to the edge given its size?

The holes on my board will be 0.7 or 0.8mm and need to be 0.8mm from the board edge for the header to fit flush on the board.