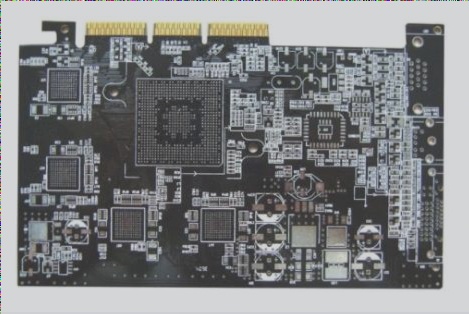

I just got back some prototype PCBs from a PCB manufacturer and I noticed that they took out the solder mask between the pads of a QFN-40, 0.4mm pitch footprint.

I asked for the reason and they said their minimum solder mask bridge is 10mil (0,254mm). This constraint is not listed in their manufacturing capabilities, btw.

How important is it actually to have solder mask between the pads? For the prototypes and hand-soldering it didn’t appear to be an issue, the PCB works as expected, would it be more critical for an actual PCBA run?