**Aluminum PCBs: Enhancing Thermal Management for High-Power Electronics**

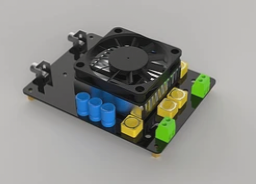

Aluminum PCBs excel in dissipating heat efficiently, making them the preferred choice for high-power applications. LED manufacturers are increasingly recognizing the benefits of aluminum PCBs due to their exceptional heat dissipation properties.

Advantages of Aluminum PCBs:

- Cost-Effectiveness: Aluminum PCBs offer cost-efficiency by reducing the need for additional cooling systems, ultimately cutting overall costs. The recyclability of aluminum further contributes to cost savings and sustainability.

- Environmentally Friendly: Aluminum-based PCBs are non-toxic and pose no environmental risks, making them a safer and eco-friendly option compared to PCBs with toxic materials.

- Efficient Heat Dissipation: Aluminum PCBs prevent overheating in high-power applications by effectively dissipating heat, protecting components and extending their lifespan.

Aluminum PCBs are the top choice for applications requiring effective heat management, offering unparalleled cost-effectiveness, environmental safety, and thermal efficiency.

Aluminum PCBs provide significant advantages in applications where heat dissipation, durability, and lightweight design are crucial. Here’s a breakdown of the benefits and uses of aluminum PCBs based on real-world industry expertise.

Effective Heat Conduction:

Aluminum’s exceptional thermal conductivity ensures efficient heat transfer away from components, maintaining stable operation and preventing performance degradation or failure, especially in high-power scenarios.

Durability:

Unlike standard fiberglass PCBs, aluminum PCBs offer superior mechanical strength, making them ideal for demanding environments like automotive, industrial, or outdoor settings. Their robustness ensures functionality even under physical stress, enhancing overall reliability.

Lightweight Construction:

Despite their strength, aluminum PCBs are lightweight, making them ideal for weight-sensitive designs in aerospace or portable electronics. Their reduced need for heat sinks further contributes to weight optimization without compromising performance.

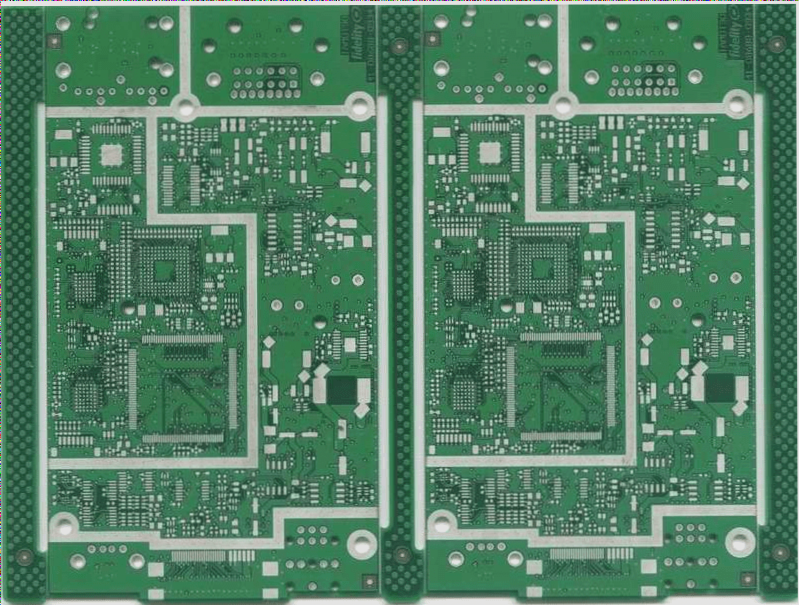

Applications of Aluminum PCBs:

Benefits of Aluminum PCBs for High-Performance Applications

Aluminum PCBs are the go-to choice for applications requiring efficient heat dissipation, mechanical strength, and long-term durability. Their exceptional thermal management properties make them perfect for power electronics, LED lighting, automotive, and other high-performance systems.

- Superior Heat Dissipation: Aluminum PCBs offer approximately 10 times better heat emission efficiency compared to traditional fiberglass PCBs, ensuring optimal thermal management.

- Compact and Efficient Design: The enhanced thermal management of aluminum PCBs allows designers to optimize the overall size of electronic products, resulting in more compact and efficient solutions.

- Reliability and Durability: With the strength and lightweight construction of aluminum, electronic systems built with aluminum PCBs are more reliable and durable in the long run.

Overall, aluminum PCBs play a crucial role in applications where thermal management, strength, and lightweight design are essential. By harnessing the unique properties of aluminum, designers can develop electronic systems that are not only more reliable but also more efficient and compact.