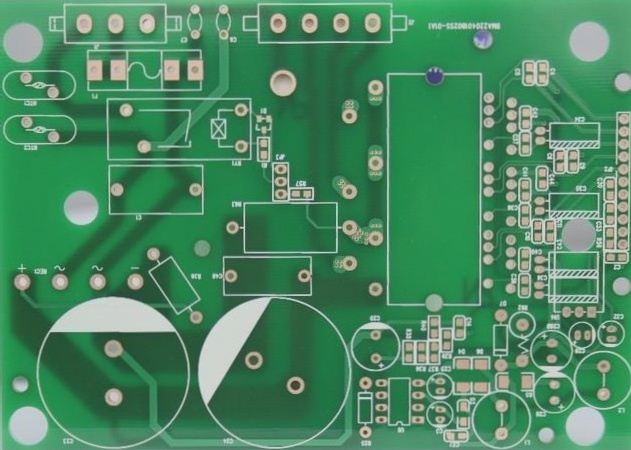

Double-Sided Etching Machine Production Line

- Features of the Production Line:

-

- This machine utilizes a PLC automatic control system and a user-friendly man-machine interface.

- Special nozzle arrangement in the PCB design ensures uniform and fast spraying.

- Separate liquid tank design prevents deformation due to high temperatures.

- Adjustable wheelbase accommodates both soft and hard boards.

- Vertical and horizontal integration of exhaust, drainage, and water systems for easy installation.

- Etching accuracy down to 4μ for precise results.

PCB Process Flow:

Loading – Etching – Ammonia Water Washing – Pump Washing I – Pump Washing II – City Water Washing – Draining – Unloading

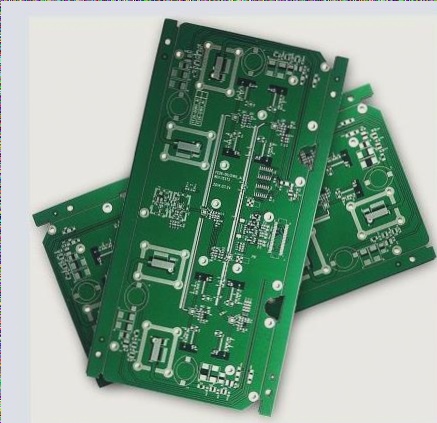

Antioxidant Production Line

- Use of the Production Line:

-

- Stable conveying system and circulating filter system create a protective film on the workpiece, enhancing oxidation resistance.

- Ideal for manufacturing PCB double-sided multilayer boards with various syrup formulas.

Technological Process:

Board Entry – Degreasing – Circulating Water Washing – Micro-etching – Circulating Water Washing – Pickling – Circulating Water Washing – DI Water Spraying – Blotting – Air Knife Drying – Antioxidation – Blotting – Air Knife Drying – Circulating Water Washing – DI Water Spraying – Vacuum Drying – Blow Drying – Far Infrared Drying – Unloading

Features of Antioxidant Production Line

- Advanced process structure design with soft transfer rollers to prevent surface scratches.

- Small wheelbase and dual transmission system for smooth passage of thin plates.

- Continuous filtration system for solution stability.

- Energy-saving PLC control systems for reduced production costs.

- Integrated drainage and exhaust systems with a transparent tempered glass window for aesthetic appeal.

Removal Film Cleaning Production Line

- Features of the Production Line:

-

- SUS high-temperature soaking zone and stainless-steel pump for effective membrane separation.

- Efficient slag removal filtration system for thorough residue removal.

- Soft scrubbing for a cleaner board surface.

- Piping design to minimize water and electricity loss, reducing production costs.

- Integrated exhaust and drainage system for operational tidiness.

PCB Equipment Process

Loading the board – soaking – stripping – brushing – washing – circulating water washing 1, 2 – municipal water washing – blotting – removing the board